How To Dry Compost

Application

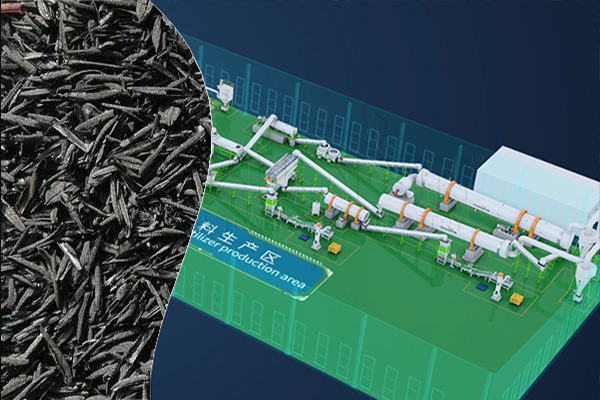

Animal manure, biogas waste, industrial organic waste compost, humus, biochar compost, etc

Capacity: 1-20 t/h

Output Mosture: lower 10%

Inlet Temperature: Higher 300 ℃

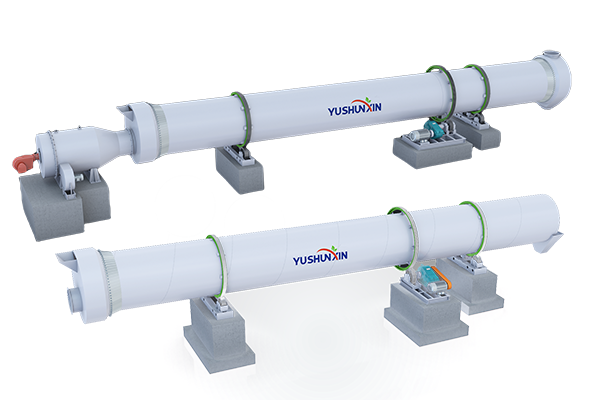

Drying compost fertilizer is a crucial step during compost pellet fertilizer making process. For one thing, it is the secrete of make granulated compost, which has features of no sticking, easier transport, long storage time, etc. Then how to dry compost? It mainly contains 3 steps: dewatering, composting and hot air drying. Among them, hot air dryer is commonly used in make organic fertilizer granules from compost. 1-20 t/h, both compost powder and pellet drying, various fuel support, etc. Welcome to contact us for your own compost drying solutions.

How to dry compost quickly?

In oder to make quality compost organic fertilizer pellets, drying us necessary. But how to dry compost quickly? You can processing organic material by the following 3 steps:

Dewatering organic manure before composting

If your organic material moisture is higher than 50%, it is advisable to process it with manure dewatering machine. Which can separate a large amount of water with solid organic material. Making use of pressing force, it can reduce the water content of organic material to 30%. Here, we cam offer you not only screw type dehydrator for 50%-80% moisture organic waste disposal, but also inclined-screen solid and liquid separator for removing excessive water from over 80% moisture manure waste management.

Make quality compost fertilizer with composting turner

In addition, for make compost pellet organic fertilizer from wet material (40%-60%), composting is also an ideal choice to reduce the moisture. For one thing, composting can eliminate the harmful substance in organic waste by high temperature. For another, because of high temperature condition, the moisture will reduce to the 30% after aerobic fermentation. Here, to help you decomposing organic fertilizer quickly, YUSHUNXIN especially design various industrial compost machines for your choice.

Use professional dryer for compost fertilizer processing

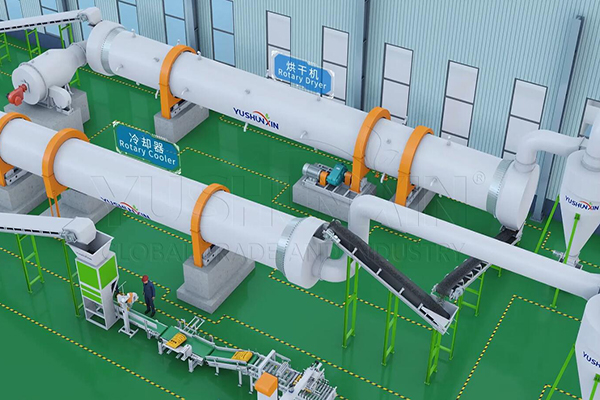

But, how to dry compost to 10% or less water content? The rotary dryer is the best choice for you. Because of hot air drying method employment, it can dry a large amount of compost fertilizer in a short time.

Why rotary dryer can dry compost to 10% moisture fast?

In the above 3 types of equipment to dry compost, only rotary dryer can dry compost organic fertilizer to 10% moisture. Why? Because, the machine have 3 unique designs can help you dry compost quickly

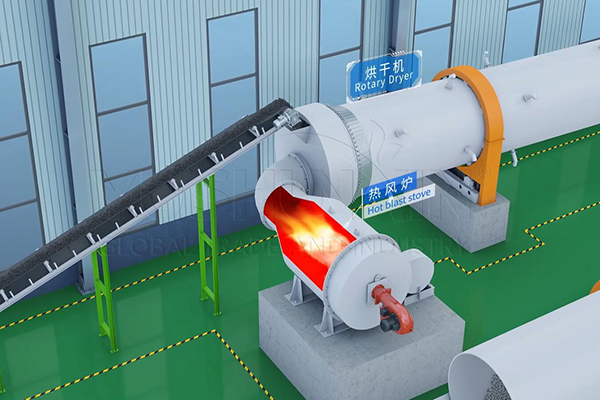

Hot air drying method employment

As mentioned above, the compost dryer mainly makes use hot air to dry organic materials. Because the temperature of drying can reach to 300 ℃, which can create an environment with 60℃-70℃. With directly contact with hot air, there is a maximizing heat transfer. Therefore, the compost fertilizer in the drum can be dried to 10% or less moisture quickly.

Rotary drum design

In addition, the drum where start the compost fertilizer drying is rotating. In this way, the compost material into the drum will move continuously. This ensures the uniform exposure of compost material to the hot air. So, the hot air can dry the composted manure evenly and quickly.

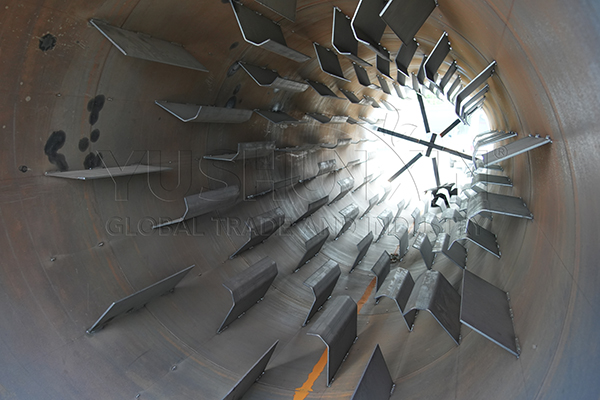

Material lifting plates design

Inside the compost rotary dryer, we also add the lifting plates. While the machine rotation, they can scoop and drop the compost. So, surface area of compost exposure to the hot air will increase. This design also enhances heat penetration and speeds up the compost fertilizer drying process.

How many compost fertilizer can the rotary dryer process?

In order to fully meet your requirements for both small scale and large scale granulated compost fertilizer production, there is 1-20 t/h compost rotary dryer for your choice

| Model | MotorPower (kw) | Capacity (t/h) | Reducer Model | Temperature of lnlet | Angle of Installation |

Speed (r/min) |

|---|---|---|---|---|---|---|

|

SXHG-0808 |

5.5 | 1-2 | ZQ250 | ≥300 ℃ | 3°-5° |

6 |

|

SXHG-1010 |

7.5 | 2-4 | ZQ350 |

≥300 ℃ |

3°-5° |

6 |

|

SXHG-1212 |

7.5 | 3-5 | ZQ350 |

≥300 ℃ |

3°-5° |

6 |

|

SXHG-1515 |

11 | 4-6 | ZQ400 |

≥300 ℃ |

3°-5° |

6 |

|

SXHG-1616 |

15 | 6-8 | ZQ400 |

≥300 ℃ |

3°-5° |

6 |

|

SXHG-1818 |

22 | 7-12 | ZQ500 |

≥300 ℃ |

3°-5° |

6 |

| SXHG-2020 | 37 | 8-15 | ZQ500 | ≥300 ℃ | 3°-5° |

5.8 |

|

SXHG-2222 |

37 | 8-16 | ZQ500 | ≥300 ℃ | 3°-5° |

5.5 |

| SXHG-2424 | 45 | 14-18 | ZQ500 | ≥300 ℃ | 3°-5° |

5.2 |

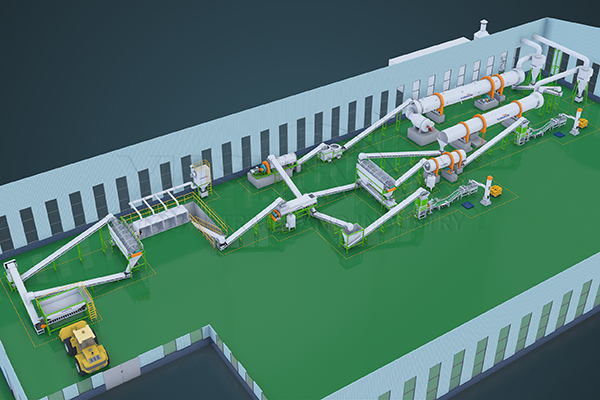

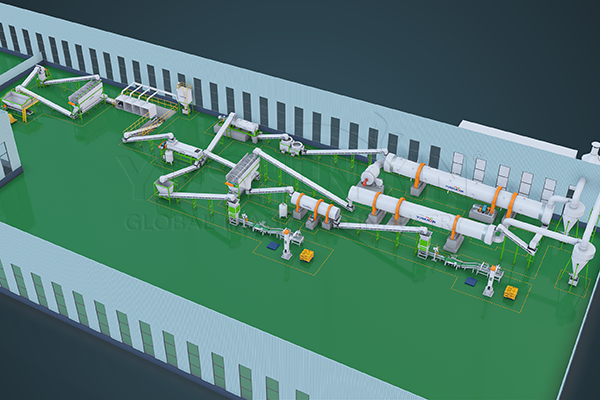

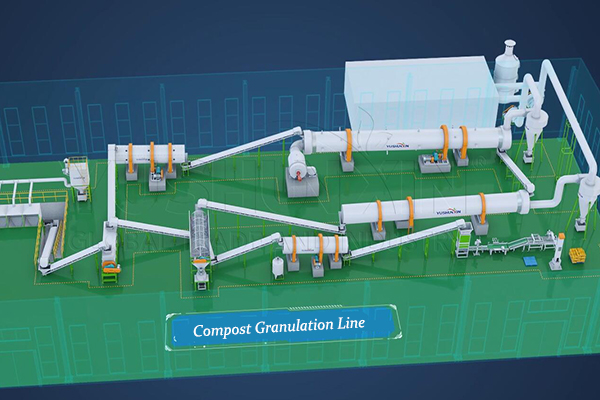

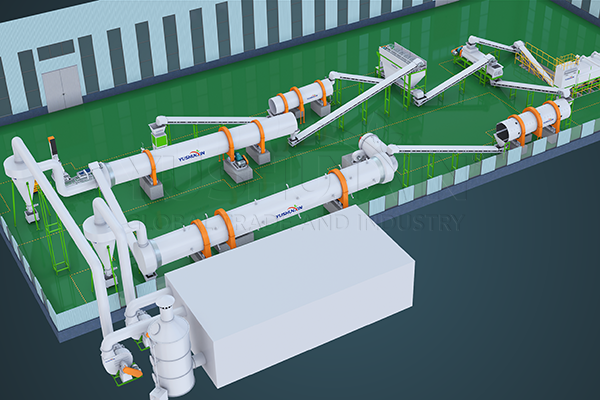

What is the role of compost dryer in compost pellet making process?

In the whole process of compost granule production, you can use the rotary dryer in two ways:

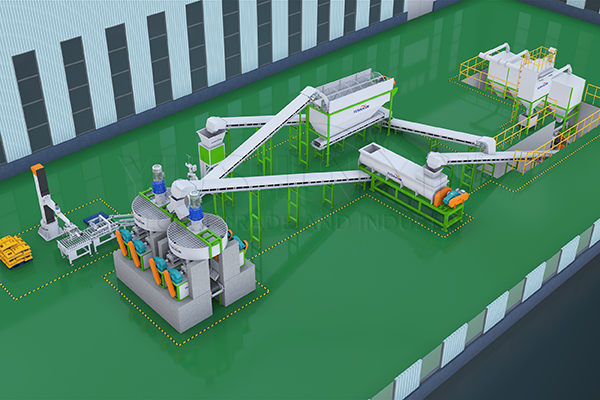

Commonly, when you use wet granulation machine of compost, it is advisable to use the rotary dryer after the compost granulator. In this way, you can ensure that the final organic fertilizer pellet you make has a moisture of lower than 10%. In general, the whole compost granulated plan design is material batching machine → crusher → mixer → wet compost fertilizer granulator → screener → dryer → cooler → packing machine.

However, during dry granulation of compost, you need to add the drying system before the dried compost granulation equipment. Because the its required moisture of feeding material is lower than 10%. Or, you can finish the drying of compost by sun. So, the layout of dry compost fertilizer granulation plant is material batching machine → crusher → mixer → screener (→ dryer → cooler) → dry compost fertilizer pellet machine → packing machine.

Besides compost drying, YUSHUNXIN also can offer you many other granulated compost solutions for your choice. Such as compost making system, compost granulation plans, compost grinding machines, etc. Welcome to contact us for your own compost organic fertilizer granulation line.

Contact Us

recently granulated compost solutions

Granular Biochar Compost Based Fertilizer Production

Project • 1-20 T/H • $50,000-$500,000

Granular Compost Fertilizer Drum Coating Machine

Auxiliary Equipment• 1-30 T/H

How To Produce Granular Biofertilizer From Compost

Project • 1-20 T/H • 1-10 mm Granules