How does flat die extrusion granulator work to prepare compost pellets?

Flat die extrusion granulator is a type of dry compost granulation machines, which makes use of extrusion force between roller and mold make organic fertilizer pelelts from compost material. There is no liquid involved, so the flat die pelletizer working process is as follows:

What kind of flat die pellet mills in YUSHUNXIN compost granulation equipment manufacturer?

In general, there are 3 models of flat die pellet machines YUSHUNXIN can offer you. They can help you produce granular compost fertilizer with 1-2.5 t/h capacity easily.

| Model | Capacity (t/h) | Power (kw) | Pellet Diameter (mm) |

|---|---|---|---|

|

SXPM-400 |

1-1.5 | 30 | 2-10 |

|

SXPM-500 |

1.5-2 |

37 | 2-10 |

|

SXPM-600 |

2-2.5 |

45 |

2-10 |

When is suitable to buy flat die pelletizer to make compost granules

According to our engineers suggestions, the flat die extrusion granulator is the best choice for granulated compost fertilizer manufactures who have following requirements

Is there extrusion granulator for large scale compost granulation plants?

If you start a compost pellets fertilizer making with 3-5 t/h ouput, there are 2 solutions for you.

Add more flat die pellet mills

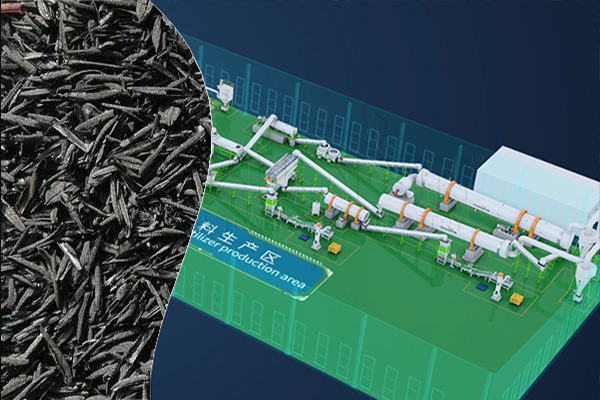

For example, when you plan to produce 5 tons of compost pellets, we can design a compost granulation line with two sets of SXPM-600 flat die granulators. In general, the compost pelleting system contains windrow compost machine, material batching equipment, SXFLF-800 vertical crusher, double shaft mixer, SXGS-1540 screener, fertilizer packing machine, etc.

How to make extruded compost pellets more rounded?

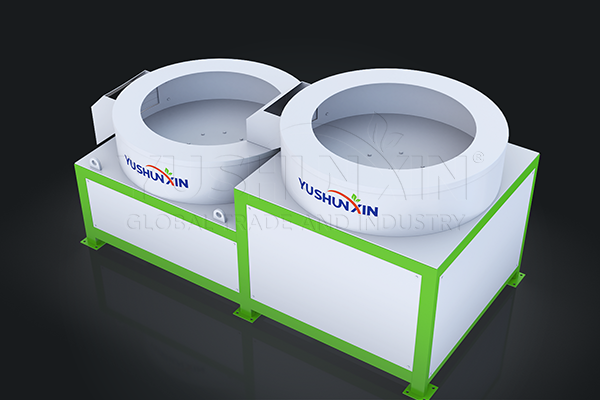

To achieve more rounded extruded compost pellets, incorporating a fertilizer polishing machine into your organic compost granulation process is an effective solution. This machine is specifically designed to enhance the shape and smoothness of compost pellets, transforming them from irregularly shaped extrusions into uniform and aesthetically pleasing spheres.

After pressing compost into column fertilizer granules, feeding them into the fertilizer polishing machine. It operates by using a rotating drum. The centrifugal force generated by the drum causes the pellets to tumble and roll against each other, gradually wearing away any sharp edges and rough surfaces. This action results in pellets that are not only more rounded but also possess a polished and smooth exterior.

Besides flat die extrusion granulator, we also can offer you double roller extrusion machines for you. It can prepare flat ball compost pellets for you. And its maximum capacity can reach to 3 t/h. In addition, for high moisture wet compost granulation, there also are disc pelletizer, rotary drum granulator and new type organic fertilizer granulation machine, etc for you. Welcome to contact us for you customized granulated compost making solutions.

recently granulated compost solutions