Dried Compost Pellets Production

Application

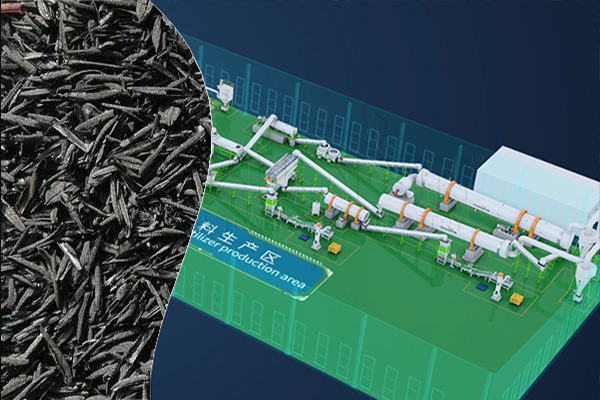

Animal manure, biogas waste, industrial organic waste compost, humus, biochar compost, etc

Capacity: 1-20 t/h

Granule Size: 3-10 mm

Granulation Rate: 90%-95%

How to make dried compost into organic fertilizer granules? If your material for organic fertilizer granulation is dried compost (lower than 20%), it is advisable to buy a dry granulation machine directly. Which mainly makes use of extrusion force to press compost powder into organic fertilizer pellets. Without water involved, you can finish the fertilizer granulation of compost simpler, faster and at a lower investment. In the process of dried compost pellets production, a suitable dry granulation machine is necessary. Here, YUSHUNXIN can offer you dry roller pressing granulator, flat die pellet mill and ring die granulator. In addition, we can offer you customized design of your dry compost fertilizer granulation plant layout.

What equipment is commonly used in dried compost pellets production?

In the production of dried compost pellets, several types of dry fertilizer granulation equipment are commonly used. Each with its specific advantages and suitable applications.

Best compost dry roller press granulator

For dry granulation of organic compost, double roller press machine is the best choice. It mainly makes use of double roller opposite moving to make compressed compost fertilizer pellets. In terms of design, the machine has advantages of over 97% granulating rate, 20CrMnTi or 4Cr13 stainless steel roller material and screen adding. Moreover, the roller compactor also suitable for making organic fertilizer granules from compost in small and large scale. Single equipment output is 1-3 t/h. But with more roller granulators, you even can setup a 10 t/h compost fertilizer granulation plant.

Lower investment flat die pellet mill

When you need a dry granulation equipment for your granulated compost making, we recommend you flat die pellet mill. The machine not only can meet you requirements of 1-2.5 t/h compost granulation, but also has a lower price and less area occupation. But, the final compost particle shape is column. Because it uses a flat die and a rotary roller to compress compost powder into organic granules. The roller press organic material into die holes, then cut into short fertilizer pellets by blades.

Ring die pellet machine for dried compost pellets production

Then, the ring die pelletizer is the upgrading version of flat die pellet mill. Similarly, it make column compost fertilizer pellets with 1-10 mm size for you. However, it has a large output of compost granules production. In the process of organic fertilizer granulation, the working principle is also similar with flat die granulation. It feeding organic compost into ring-shaped die. Then the centered roller will press material into the ring die. Finally, the finished compost rods will be cut by rotary scrapers.

| Equipment | Capacity (t/h) | Granule Size (mm) | Granulation Rate | Feeding Moisture |

|---|---|---|---|---|

|

Double Roller Granulator |

1-3 | 3-10 | 95% | 5%-20% |

|

Plat Die Pellet Mill |

1-2.5 |

2-10 | 95% | 5%-20% |

| Ring Die Pellet Machine |

1-5 |

4-10 |

90% |

5%-20% |

How much does a dry granulation machine cost?

Besides function, dry granulation machine price also plays an important role in buy a suitable granulator for dried compost to organic fertilizer pellets. There are some information for your reference.

For the most precise pricing of compost pellet machine you need, Welcome to contact us immediately.

3 Benefits of dry granulation machine over wet granulation equipment in granulated compost making?

Compared with wet granulation method, dry granulation has its unique advantages. This is the reason way so many compost pellet fertilizer manufactures favor the the dry granulation equipment of compost. In general, the top 3 benefits are

Make dried compost pellets faster for you

In addition, this is also beneficial for produce organic fertilizer granule from dried compost quickly.

Reduce your cost of organic fertilizer granule making

Dry granulation helps reduce the overall cost of organic compost fertilizer granule making in several ways:

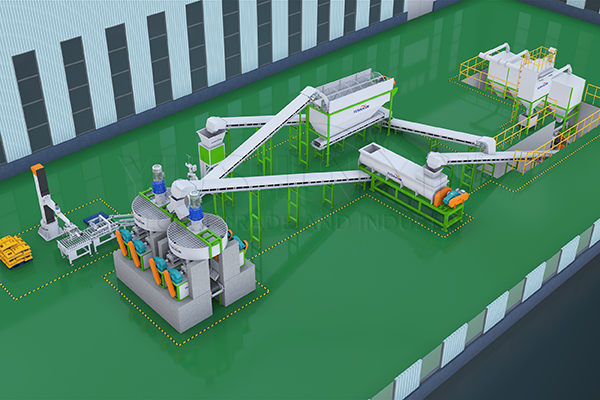

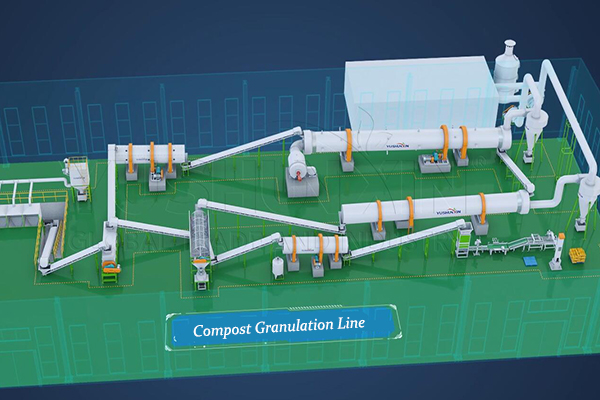

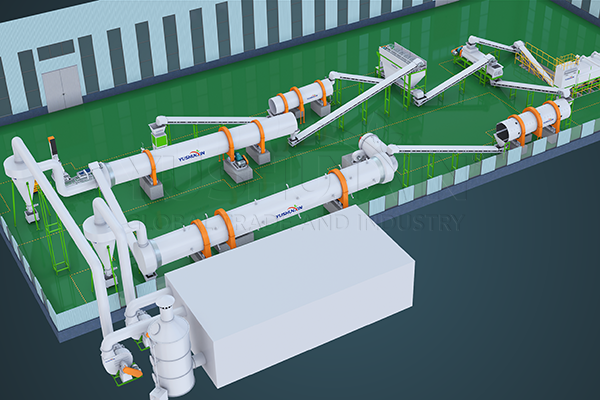

What is the layout of an dry compost pellet making plant?

If you want to setup a compost fertilizer granulation plant with dry granulation, you need to prepare 3 areas at least.

– Purpose: Storage of raw compost material before processing. Or with composting making.

– Key Features: Large flat ground that easy access for loading and unloading. It is advisable add a shelf for rain prevention.

– Purpose: installation of the dry granulation line for granular compost fertilizer making.

– Key Features: a complete dry granulation process including equipment of batching machine, crusher, mixer, dry compost granulator, screener and packing machine.

– Purpose: Store finished products and prepare them for shipping.

-Key Features: Shelving or pallet racking systems, loading docks, and access for organic fertilizer pellets transportation vehicles.

Only send us details of equipment you need and area information, our engineers can design a customized layout for your compost organic fertilizer granulation plant.

Cutomer feedback for YUSHUXN dry granulation line for compost pellet making

At present, we have help many customers start their organic granulation plants with the system. They all have good feed back for our dried compost pellet production line.

As a professional granulated compost solutions and machine provider, YUSHHUNXIN can offer your both dry and wet granulation plan of compost. Including chicken manure compost pellet plan, cow dung compost granulation line and 2 t/h, 5 t/h, 10 t/h, etc. Welcome to contact us for your own compost granulation business plan.

Contact Us

recently granulated compost solutions

Granular Biochar Compost Based Fertilizer Production

Project • 1-20 T/H • $50,000-$500,000

Granular Compost Fertilizer Drum Coating Machine

Auxiliary Equipment• 1-30 T/H

How To Produce Granular Biofertilizer From Compost

Project • 1-20 T/H • 1-10 mm Granules