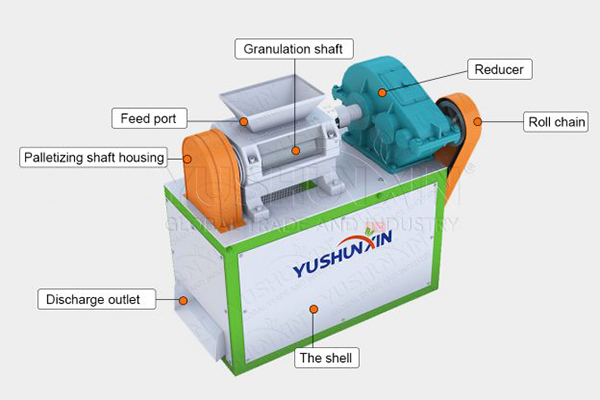

What are the advantages of using a double roller press granulator for compost pelleting?

Why so many organic fertilizer manufacturer start to buy a double roller press granulator to make compost granules? Because the machine has advantages for compost pelleting projects as follows .

Help you finish granulated compost making at a low cost

If you need an economical price compost pellet machine, the double roller extrusion machine is an ideal choice. For one thing, the compost pellet machine has a economical price. A double roller press granulator only needs $3,000-$12,000. For another, in the process of compost fertilizer granulation with roller pelletizer, you can save the expense of compost drying machine purchasing.

Quickly making composted manure into fertilizer granules

In addition, because dry extrusion granulation method employment, only need once pressing, you can convert organic compost material into organic fertilizer granules. It not only save the time of fertilizer granule formation but also subsequent drying.

Both suitable for small and large scale compost granulating

What is the capacity of the roller press granulation machine? Is it suitable for small / large scale compost pellet making plants? In general, a set of double roller press granulator can produce 1-2 tons of granular compost fertilizer per hour. But, if you want to enlarge the scale of your pelletized compost fertilizer making business, the method is simple. Only need to use more fertilizer roller granulators. For example, for 10 t/h organic fertilizer granulation plant, you need to buy 6 sets.

| Model | Capacity (t/h) | Power (kw) | Granule Diameter (mm) | Roller Sheet Size (mm) |

Dimensions (mm) |

|---|---|---|---|---|---|

|

SXDG-1T |

1 | 15 | 3-10 | 150*220 | 1450*800*1450 |

| SXDG-1.5 T |

1.5 |

18.5 | 3-10 | 150*300 |

1450*850*1500 |

|

SXDG-2T |

2 |

22 | 3-10 | 150*300 |

1630*850*1650 |

3 steps of roller extrusion granulator to make granulated compost for you

Because the double roller pelletizer adopts dry granulation method, which relies on the compress to granulate organic compost. At the same time, the requirement of feeding material moisture is 5%-20%. For making dried compost powder into organic fertilizer pellets, double roller only needs 3 steps.

Does the roller extrusion granulation process need to dry compost with dryer?

You can consider it according to your actual conditions. If you want to finish the production of organic fertilizer pellets from compost faster, it is advisable to add a rotary dryer machine before double roller granulator. Our rotary drying machine can create an environment of 60℃ temperature, which can dry compost fertilizer granules to 10% in a short time. However, if your budget for compost pellet making is limited, you can choose to aging compost for drying.

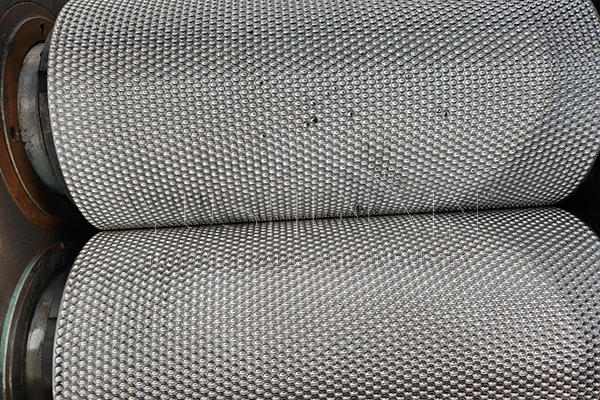

What is the material of roller sheet of compost fertilizer roller press granulator?

Generally, YUSHUNXIN manufactures double roller press granulator of composting with 20CrMnTi steel material. Which can process 500-1000 tons of organic compost into fertilizer granules. Namely, you need to change the roller sheets at about half a year. Moreover, if you need, we can replace it with 4Cr13. It is a kind of stainless steel alloy, which has a better performance in erosion resistance.

What is the price of double roller press machine and system for compost pelleting

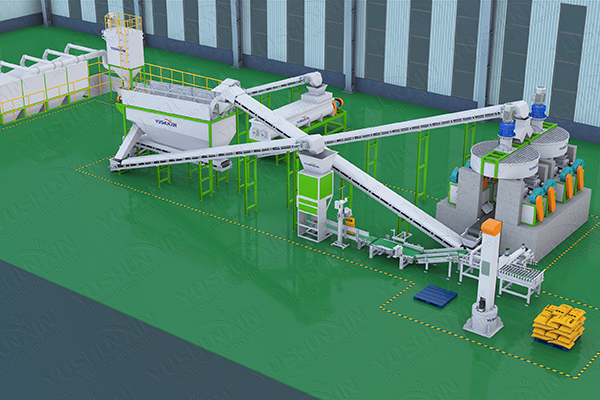

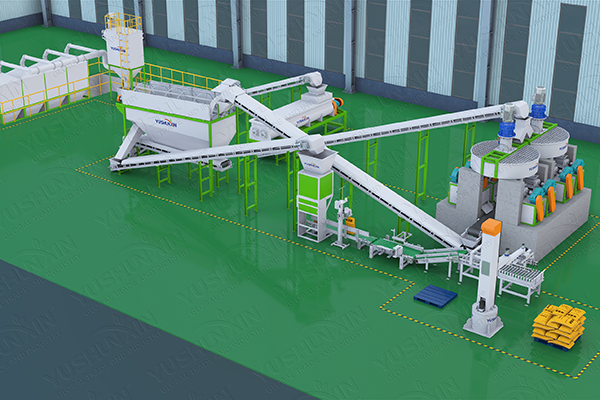

As mentioned above, the price of double roller pellet machine for compost processing is $3,000-$10,000. As for the compost pelleting making systems with roller extrusion granulator, the cost will fluctuate with capacity, layout, etc. There are examples of 2 t/h and 10 t/h double roller organic compost fertilizer granulation lines costs for your reference.

The price of 2 t/h roller press granulation system of compost

For 2 t/h compost granulation plant setup, we recommend buy compost machines including: loader type feeder, SXFLF-600 vertical crusher, SXGS-1240 rotary screener for compost powder, SXDG-2T roller press granulator, single bucket fertilizer packing equipment and belt conveyor. For this, you need to prepare about $10,000-$50,000 (reference) for it.

The cost of 10 t/h compost pellet machines

But for 10 t/h double roller granulation line of compost, we recommend you use machines that dynamic batching machine, SXFLF-1000 vertical crusher, SXGS-1560 rotary screener for compost powder, double shaft horizontal mixer, SXDG-2T roller press granulator * 5, double bucket fertilizer packing equipment and belt conveyor. It is also an ideal choice for make compost pellet with various materials. In general, the cost of the system is $50,000-$100,000 (reference).

In addition, if you need industrial compost turner and manure dehydrator for compost making and rotary dryer and cooler, the price of compost granulation line is $10,000-150,000. If you want to get the precise quote of your double roller press granulation system, welcome to contact use immediately.

If you need other machines for compost granulation, welcome to contact us now! There are also economical disc pelletizer, large scale drum granulator, stirring teeth granulation machine, etc for you chocie.

recently granulated compost solutions