Disc Pelletizer For Compost Fertilizer Granulation

Application

Animal manure, biogas waste, industrial organic waste compost, humus, biochar compost, etc

Capacity: 1-6 t/h

Granule Size: 1-8 mm

Granulation Rate: 93%

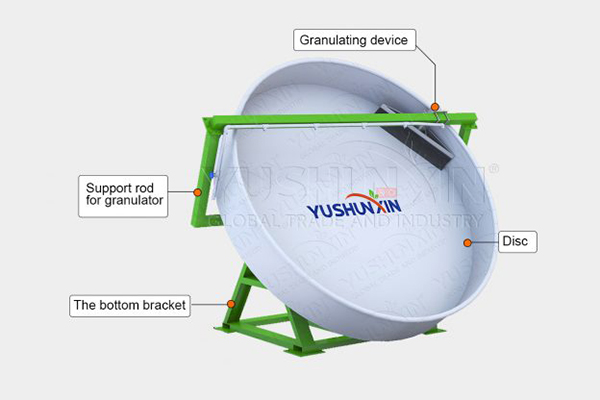

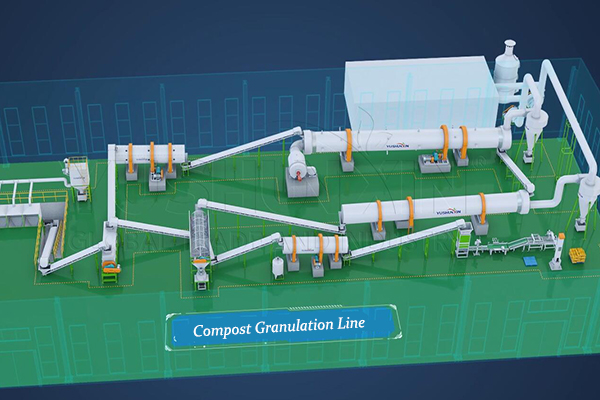

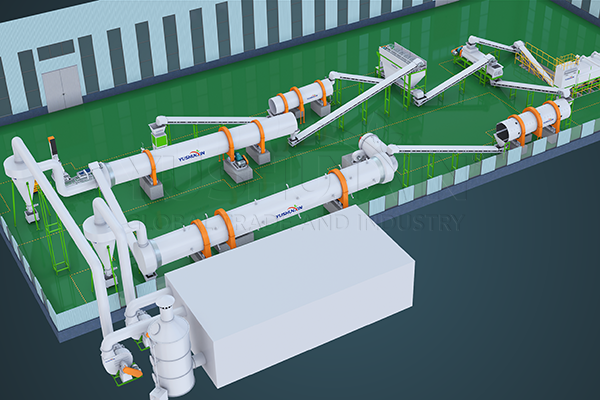

The disc pelletizer, also known as a pan granulator, is an essential machine for the granulation of compost in the fertilizer making industry. It employs wet granulation method, which makes compost powder form into round fertilizer pellets quickly. In addition, because of economical price, small area occupation, adjustable granule size, etc, the machine is hot selling for both small and large scale granulated compost fertilizer manufacturers. If you want to setup a compost fertilizer granulation plant with disc pellet equipment, welcome to contact us for your own granulated compost making plans.

How does the disc granulator work to make organic fertilizer granules from compost?

A disc granulator is an equipment that efficiently converts composted organic fertilizer into uniform pellets. This granulation process of compost can be divided into 4 parts:

Feeding compost powder into the disc

The compost fertilizer granulation process starts by feeding the compost powder into the disc (pan). The disc is set at an angle and is typically shallow.

Adding liquid to the compost material

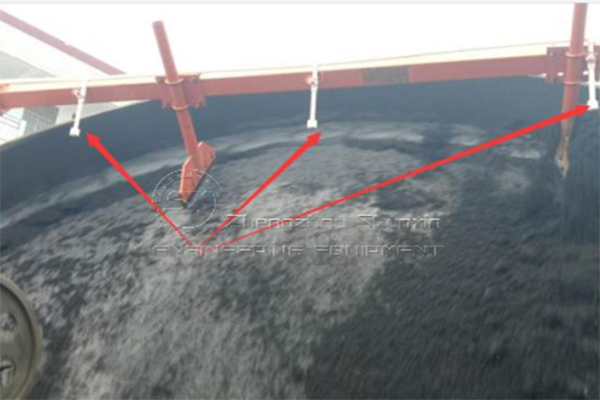

While the compost usually contains some moisture, you also need additional liquid, such as water or binder. This ensures the compost particles stick together and form into organic fertilizer pellets fast. Here, we can offer you disc pelletizer with spray device.

The disc rotates to make compost fertilizer pellets

As the disc starts rotating, the combined forces of gravity, centrifugal action, and friction help the particles within the compost to stick together.

Discharging granulated compost

Gradually, these compost pellets increase in size until they reach the diameter you need. Because of centrifugal action, the finished granulated compost will be discharged.

What scale of compost pellet making project does pan granulator suitable for?

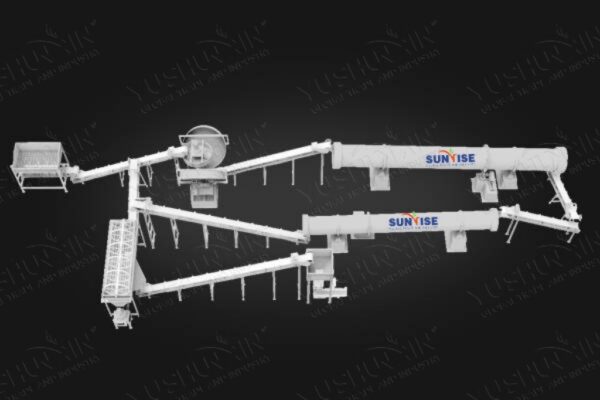

In general, a disk compost granulating machine has a capacity of 1-6 t/h. This can fully meet your requirements of small scale compost powder granulation. Can the disc pelletizer make organic compost pellets in a large scale? The answer is yes. You only need to increase the number of pan granulator. For example, if you plan to set up a 10 t/h compost fertilizer granulation plant, you need to use two SXYZ-3600 disc pellet machines.

| Model | Capacity (t/h) | Diameter (mm) | Motor Power (kw) |

Dimensions (mm) |

|---|---|---|---|---|

|

SXYZ-1800 |

0.8-1.2 | 1800 | 3 | 2060*1700*2130 |

|

SXYZ-2000 |

1.2-1.5 |

2000 | 4 |

2260*1650*2250 |

|

SXYZ-2500 |

1.5-2.0 |

2500 |

7.5 |

2900*2000*2750 |

|

SXYZ-2800 |

2.0-3.0 |

2800 |

11 |

3200*2200*3000 |

|

SXYZ-3000 |

2.0-4.0 |

3000 |

11 |

3400*2400*3100 |

|

SXYZ-3600 |

4.0-6.0 |

3600 |

11 |

4100*2900*3800 |

How about the granulated compost products discharged from disc pelletizer?

Then, the best way to buy a suitable granulation machine of compost is looking the final granulated compost fertilizer. Such as granule size, moisture, granulation rate, etc. How about these of compost pellets from disc pelletizer?

1-8mm Granule size

Generally, pan granulation machine can fully meet you requirements of making composted organic waste into fertilizer pellet with 1-8 mm diameter. With the adjustment of water content and disc angle, you can control the compost granules size freely.

20% Moisture Cotent

What is the moisture after the dis granulation of compost? Usually, it is 20%. Can we reduce the water content of final pelletized compost to 10%? It is advisable to use a rotary dryer after disc granulation.

93% Granulation rate

In terms of granulation rate, the pan granulator can reach 93% and even more. This means you can make more pellets from the same volume of compost material. Therefore, in large scale compost fertilizer granulation plant, manufactures choose to add a disc pellet machine after the rotary drum granulator.

If you want to learn the granulation effect of your compost material, we can offer you the service of machine testing. You can choice to send us you material or visit our factory, which is located in Xingyang City, Zhengzhou City, Henan Province, China.

How to further improve the quality of your compost pellet from disc pelletizer?

With compost screener, you can remove waste and sieve out granulated compost with required size. This is crucial for prepare compost pelletizer with uniform size.

Lastly, proper packaging is vital for preserving pellet quality during storage and transport. It protects against moisture, contamination, and physical damage. Here, automatic packing machine can help you a lot.

Moreover, if you need other granulators for compost processing, you also can contact us. YUSHUNXIN can offer you rotary drum pelletizer, roller press granulator, new type organic fertilizer granulator, etc. They can meet you all requirements for granulated compost fertilizer production. Whether it is small scale or large scale, wet or dried compost material, etc.

Contact Us

recently granulated compost solutions

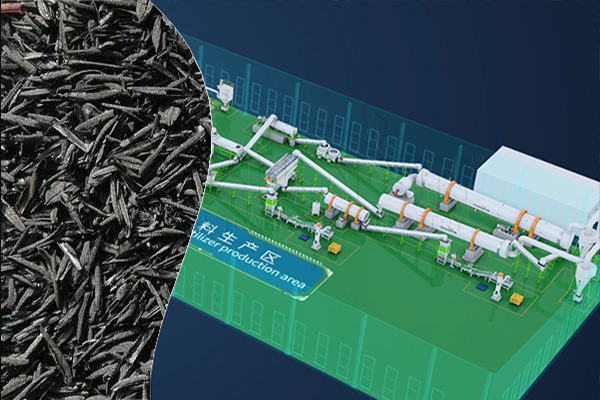

Granular Biochar Compost Based Fertilizer Production

Project • 1-20 T/H • $50,000-$500,000

Granular Compost Fertilizer Drum Coating Machine

Auxiliary Equipment• 1-30 T/H

How To Produce Granular Biofertilizer From Compost

Project • 1-20 T/H • 1-10 mm Granules