What can compost screener do for quality compost pellet making?

If you want to make quality organic fertilizer granules from compost, we recommend you buy compost screener. Here’s how it contributes to the process:

What types of compost screener on sale in YUSHUNXIN?

Whether you want to sieve powdery compost or granulated compost fertilizer, YUSHUNXIN can provide your with suitable commercial compost screening equipment.

Fertilizer sieving machine for powder compost

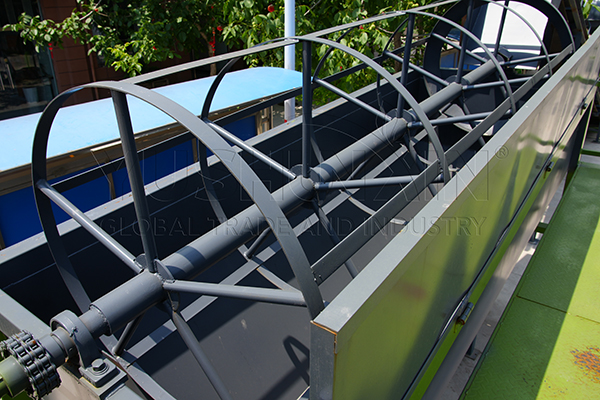

For those who want to remove waste or agglomerates from composted organic fertilizer, powder compost screening machine is the best choice. In general, the powdery compost screener has two discharging port. The large one is for discharging fine compost powder while the small one is for discharging waste or compost with large particle size.

Pellets compost screener for sale

At the same time, there is professional fertilizer screener for compost pellets sorting. Different from the above type, the compost granules screening machine has three outlets. Because it should to separate the granulated compost into 3 parts. Including small compost pellets, large composted fertilizer granules and organic fertilizer particles you want to prepare, such as 3-5 mm (can be customized).

How does the compost screening equipment work to sort finished compost fertilizer?

The rotary screener of compost mainly makes use of sieve screen rotation to sort compost powder and granules into different particle size. There is a step-by-step overview of the compost screening process:

Compost feeding

In general, most compost granulation plants prefer to use belt conveyor to feed compost into fertilizer sieving machine. Because it can transport a large amount of organic compost evenly and quickly.

Rotation and Screening

Then, with the rotation of screen, compost powder or granule fertilizer will move in the mesh. Smaller compost fertilizer particles fall through the finer meshes, while larger particles will move to the other outlets.

How many compost fertilizer can the compost screener process per hour?

In order to fully meet your requirements for organic compost granule production, we especially design compost screening equipment with capacity of 1-20 t/h. The main technology parameters of the compost screening machines are here.

| Model | Power (kw) | Reducer | Drum Speed (r/min) | Capacity (t/h) |

|---|---|---|---|---|

| SXGS-1020 | 3 | ZQ250 | 21 | 1-2 |

| SXGS-1030 | 3 | ZQ250 | 21 | 2-3 |

| SXGS-1240 | 4 | ZQ250 | 18 | 3-5 |

| SXGS-1540 | 5.5 | ZQ350 | 16 | 5-8 |

| SXGS-1560 | 5.5 | ZQ350 | 16 | 6-10 |

| SXGS-1870 | 7.5 | ZQ400 | 12 | 10-15 |

| SXGS-2080 | 11 | ZQ400 | 12 | 10-20 |

What is the material of compost screener?

The material of compost fertilizer sieving machine is also an item you must pay attention to. Because, this is closely related to the quality and service life of the fertilizer machine. In general, our compost screening equipment adopts carbon steel as main material. But we will galvanize the screen mesh, which is the wearing part. Compared with compost screeners from other factories which use nylon material, it has better performance in erosion resistance and works for your compost fertilizer granulation plant for a long time.

How to control the dust generation in compost screening?

If you are worried about the dust pollution in the process of compost granulation screening, our engineers can also offer you the best solutions.

Generally, all compost screening equipment from YUSHUNXIN has dust shields. They can prevent the dust disperse partially. In addition, if you need a compost screening machine with better dust reduction effect, we can add a closed dust cover to the machine. In this way, the compost screening will be done in a closed space.

Moreover, you also can choose to add dust cover on the belt conveyor. These covers act as barriers that contain the dust within the conveyor system.

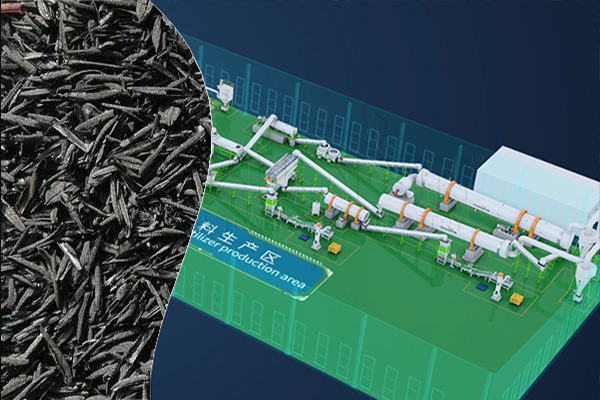

Where need to use the compost screening machine in the process of make organic fertilizer granule from compost?

As mentioned above, it is advisable to add compost sieving machines before granulation and after compost pelleting but before the drying. Therefore, the general design of a complete compost pellet making plan is dynamic batching machine → compost grinder → mixer → powder compost screener → compost granulator → granular fertilizer screening machine → compost dryer and cooler → fertilizer packing equipment. If you use fresh organic waste as material to make compost pellets, you may also need manure dehydrator and industrial composting turner.

Why not screen compost pellets after drying and cooling?

Besides, compost screening equipment, YUSHUNXIN also can provide you with many other machines for granulated compost fertilizer manufacturing. Including compost granulator, compost dryer, industrial composting machine, packing equipment, etc. Welcome to contact us for your own solutions for compost fertilizer granulation plant.

recently granulated compost solutions