Compost Mineral Fertilizer Granulation Plant

Application

manure compost with limestone, bentonite, phosphate rock, zeolite, etc

Capacity: 1-30 T/H

Granulation Rate: 90%-97%

Granule Size: 1-10 mm

If you plan to add mineral material like lime, phosphate rock, etc in compost granules making, there are 2 solutions suitable for you. Powder granulation system and granules mixing plan. In addition, we also offer you ore rocks crushers for you. They can fully meet your requirement of 1-30 t/h compost mineral fertilizer granulation plant setup at a economical price. Welcome to contact us for your own compost granulation plan now!

Top 2 Solutions for Mineral Fertilizer Granulation with Compost

In general, for those who want to produce compost fertilizer pellets with mineral material adding, there are 2 solutions are popular with the manufacturers.

Mixing compost with mineral powder to make fertilizer pellets

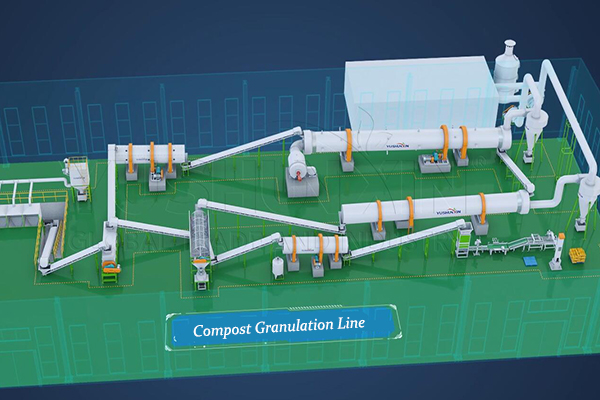

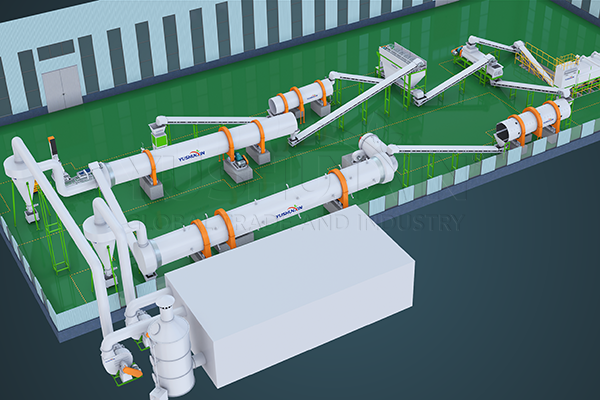

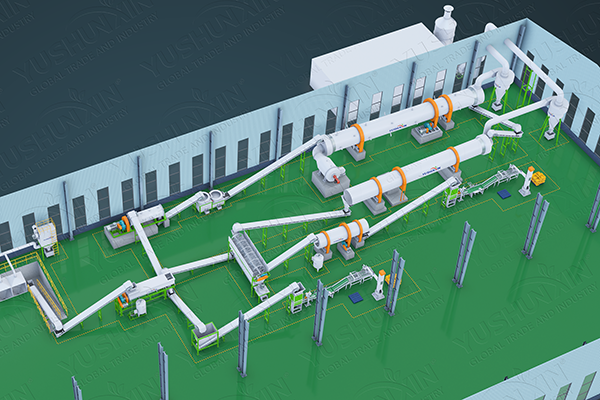

If you material is powder compost, the compost mineral fertilizer granulation line is the best choice. It can produce organic compost granules with deeply mineral nutrients incorporation. Because the system will mixing compost with mineral rocks evenly before organic fertilizer granulation.So, the whole process of the compost mineral fertilizer granule making may contains batching machine, crusher, mixer, granulator, screener, dryer, cooler, coating machine and packaging scale.

Compost and Mineral Fertilizer Granules Mixing Plant Setup

However, provided you use granulated compost fertilizer as material and only want to upgrade its nutrient content by mineral material adding, you can choose to buy a bulk blending system. It will blend granulated compost pellets with mineral fertilizer granules evenly. What a simple process. So, it only needs 3 fertilizer machines. Material batching equipment, BB fertilizer mixer and granule fertilizer packaging machine.

What compost and mineral fertilizer granulation technologies can be used?

Whether you plan to choose to produce granular compost mineral fertilizer by powder granulation or pellets blending, right fertilizer granulation system purchasing is important.

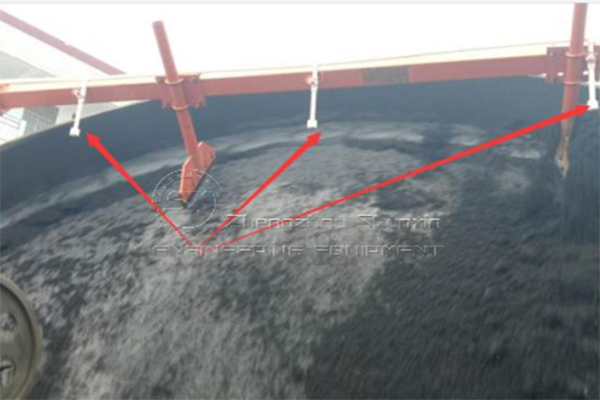

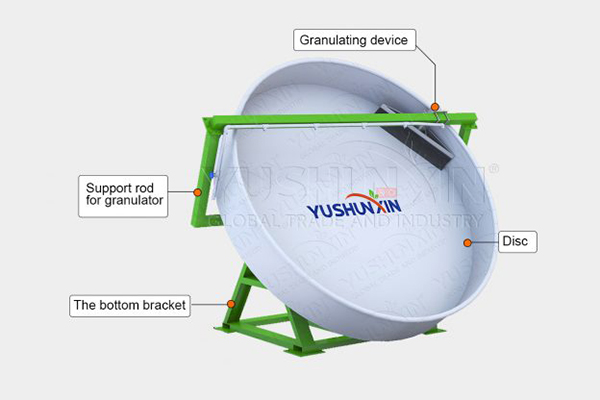

Wet Granulation of Compost and Ore Rocks

When you use wet compost as material to prepare round ball compost pellets with mineral material, system with wet granulation technology is the best choice. Because this process use water as a binding agent to facilitate the granule formation from the mixture of compost and minerals. In addition, there are various wet compost granulators, which can fully meet you requirements for granular mineral compost fertilizer manufacturing. Such as disc pelletizer line with 93% granulation rate, rotary drum granulation plan for both small and large scale 1-30 t/h granulated mineral compost making, stirring teeth granulating system for high hardness particles production, etc.

Dry Extrusion Granulation of Mineral Compost

For a more economical option, dry extrusion granulation is another popular technology used to produce compost mineral fertilizer pellets. This method involves compressing the mixture of compost and minerals into granules without the need for water or liquid binding agents. Namely, it required a material feeding moisture of 5%-20%. Moreover, the dry extrusion method is also suitable for producing pellets from various mineral rock powder materials, offer you 3-10 mm particles. For this, there are double roller granulator and flat die pellet mill for you choice. The former can offer you 3-10 mm flat ball mineral compost fertilizer pellets. The latter will produce 2-10 mm column fertilizer pellets from compost and ore materials in a limited area.

How to Grind Mineral Rocks into Powder for Compost Mineral Fertilizer Pellets

How about use large mineral rocks material to produce mineral compost fertilizer particles? How to break mineral rocks into fine powder? There are Jaw crusher and Raymond mill in YUSHUNXIN for you.

First, if your mineral material for compost granule making is over 30 mm size, you need to use Jaw crushers to break it into smaller pieces. It mainly makes use of two opposing jaws to crush material. One jaw is fixed, while the other moves back and forth, compressing and breaking down the material into smaller pieces.

After the rocks have been broken down primarily, the Raymond mill is used to grind the material into fine powder. 80-1000 mesh. This mill is highly efficient and can process a variety of minerals, including limestone, phosphate rock, and zeolite, into fine powder suitable for compost granulation. In addition, the processing capacity can reach to 10-300 t/days.

How Much Does the Compost Mineral Fertilizer Granulation Plant Cost?

The cost of setting up a compost mineral fertilizer granulation plant depends on the design and capacity of the business plan and production. Taking the above 2 types of mineral compost granule making plan as example.

Powder granulation line investment

For a powder compost mineral fertilizer granulation line, the price typically ranges from $100,000 to $500,000. This price includes the necessary equipment for mineral rocks grinding, compost mixing, granulating, drying, cooling, packing, etc. When it comes to roller granulation line, it may only needs a $50,000-$400,000 investment.

If you want to get more precise quote of compost pellet granulation line you need, welcome to contact us now!

Can the Plant Process Limestone for Preparing Compost Pellet Fertilizer?

The answer is yes. All the equipment used in the compost mineral fertilizer granulation adopts Q235 carbon steel + stainless steel. In this way, they can dispose of most all materials with high hardness and high erosion. Of course. It contains making compost granules with limestone. Moreover, it also can fully meet your requirements of mineral compost fertilizer manufacturing with bentonite, phosphate rock, zeolite, etc.

If you also have any other question about making compost pellets with mineral material, welcome to contact YUSHUNXIN immediately. We will offer you the best solution as soon as possible. In addition, we also can provide you many other granulated compost making. Such as chicken manure compost granulation plant, cow dung compost pellets making line, biogas waste compost to organic fertilizer pellets system, etc.

Contact Us

recently granulated compost solutions

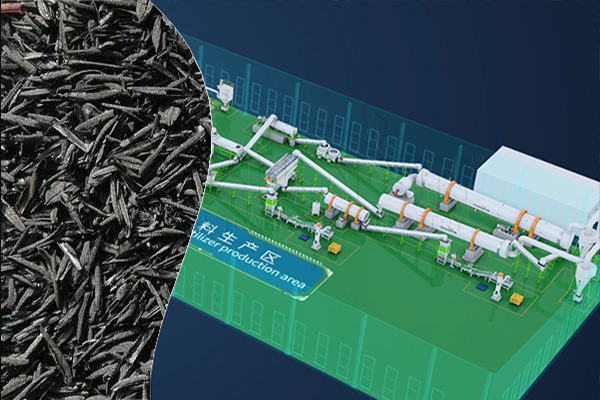

Granular Biochar Compost Based Fertilizer Production

Project • 1-20 T/H • $50,000-$500,000

Granular Compost Fertilizer Drum Coating Machine

Auxiliary Equipment• 1-30 T/H

How To Produce Granular Biofertilizer From Compost

Project • 1-20 T/H • 1-10 mm Granules