The work principle difference between dry and wet granulation of compost

What is the dry granulation equipment working method?

Dry granulation method involves compressing the compost material without the addition of any liquid. This method utilizes mechanical extrusion force to compact the material into dense pellets. Often, it compress the compost into larger compacts or flakes and then mill into smaller granules.

How the working process of wet granulator machine?

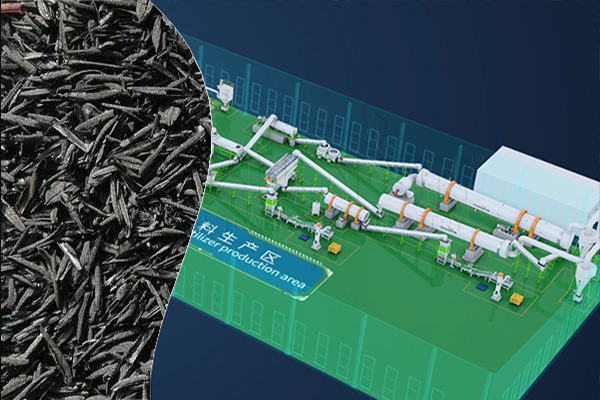

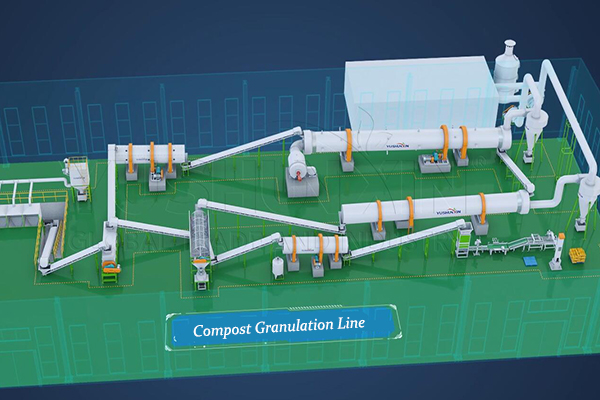

Wet granulation method involves adding a liquid binder to the compost material to form a wet mass, which is then granulated and dried. Most organic fertilizer manufacturers choose the method because of its ability to produce strong, uniform compost fertilizer pellets.

What is the largest difference in key steps of compost dry and wet granulation?

The largest difference in compost granulation process of dry and wet granulation line is drying and cooling. As mentioned above, the wet granulation of compost use liquid as binder. Usually, the moisture of compost fertilizer after granulation is 12%-20%. But, for easier to store and transport, it is advisable to reduce the granulated compost moisture to below 10%. So, it needs dryer and cooler in subsequent processes. Hence, the general steps of dry and wet granulation is as follows.

Key Steps of dry compost granulation

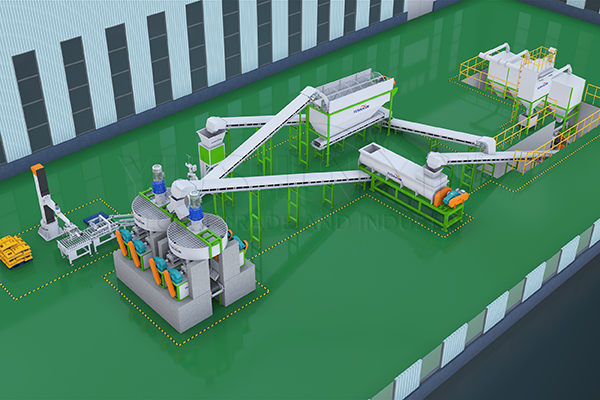

Compost material feeder → compost crushing machine → fertilizer mixer → double roller granulator / flat die pellet machine → granule screener→ fertilizer bagging equipment.

Machines used in wet compost pellet making

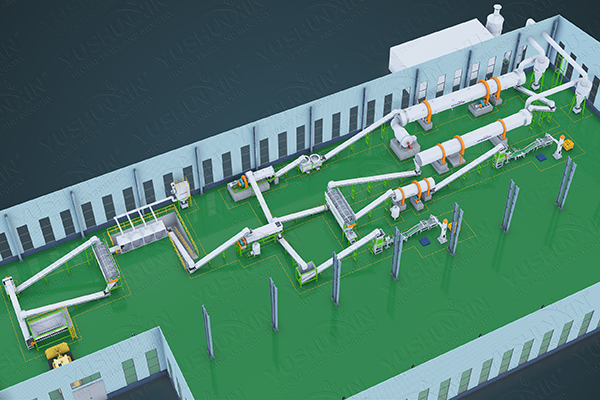

Material bathing machine→ compost grinder → compost mixing equipment → disc / new type / drum granulator→ compost sieving machine→ compost dryer and cooler → automatic packing machine.

Top 3 advantages of dry and wet granulation

Advantages of dry granulation for compost processing

Benefits for making compost pellets with wet granulation method

Provided you want to use over 20 moisture material to make compost pellets with round ball shape, we recommend you buy wet granulation machines.

The above the top 3 difference between dry and wet granulation. They have their own sets of advantages and limitations, making them suitable for different scenarios in compost pellet making. Dry granulation is energy-efficient and suitable for moisture-sensitive materials. On the other hand, wet granulation offers better pellet strength and versatility but involves additional steps like drying. You can choose the better one according to your actual conditions.