What we need to focus on when make compost pellets from fresh manure?

Compared use fermented material to make compost granules, you need to some pre-treatments when use fresh manure waste. In general, it consists of two parts. Dewatering and aerobic fermentation.

Removing excessive water from fresh manure

Generally, fresh manure has a high moisture – over 70% and even 90%. But the premium moisture for compost pellet making is 20%-45% and less. So, it is necessary to dry manure material before organic compost granulation. Then, for remove excessive water from fresh manure quickly, we recommend you buy a manure dehydrator. There is not only screw type dewatering machine for drying manure with 50%-80% moisture, but also inclined-screen solid and liquid dehydrator for disposing of manure waste with over 80% water content.

Decomposing manure to eliminate harmful substances

As the name suggest, the material compost pellet making is fermented manure. Because, in fact, the composting is a harmless process of fresh manure. It can kill the pathogens, pest eggs and grass seeds in manure. So, you can make granulated compost fertilizer with rich nutrients and no harms. And if you want to finiah the aerobic fermentation of organic waste fast, using a suitable compost equipment is the best choice. Here, we can offer you economical windrow composting turner, large scale wheel type composting machine and fast in-vessel compostor.

Come to get best solutions for granulated compost making

Moreover, when you want to make compost pellets from fresh manure, granulation machines are also necessary. You can choose the best one according to your needs.

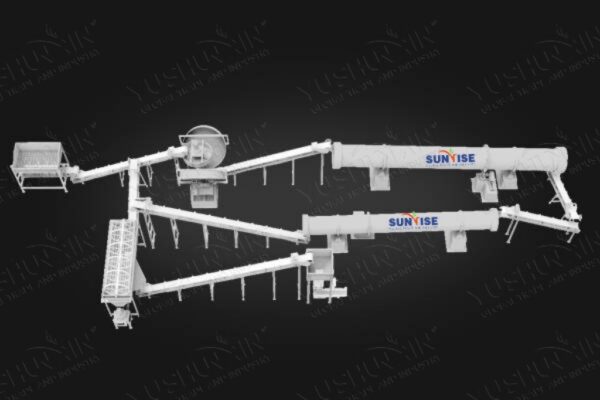

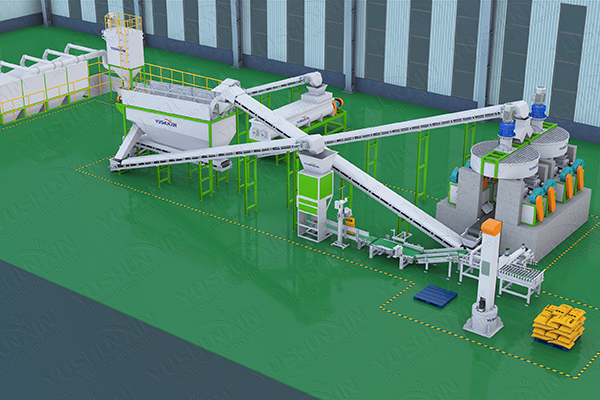

Disc granulation line for small scale compost fertilizer granulation plant

Disc granulation is an excellent method for small-scale compost pellet production. With 1-6 t/h capacity, it also has characteristics of over 93% granulation rate, 1-8 mm size compost pellet making, etc.

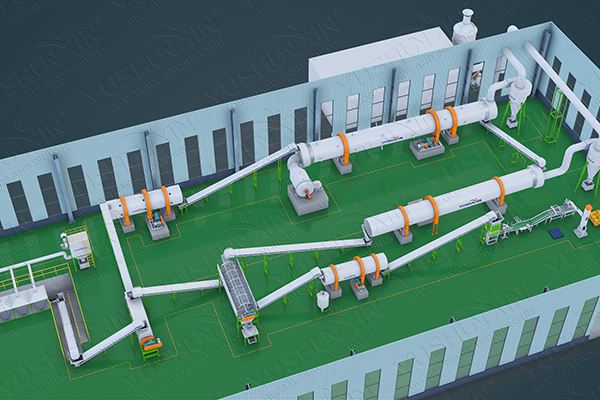

Rotary drum granulation solution for industrial compost pellet making

But, when you plan to start a industrial compost granulation plant, we recommend you buy rotary drum granulation line. For on thing, besides small scale granulated compost manufacturing, it also has models for mass compost granule production. The maximum output one can produce 30 tons of organic compost pellets per hour.

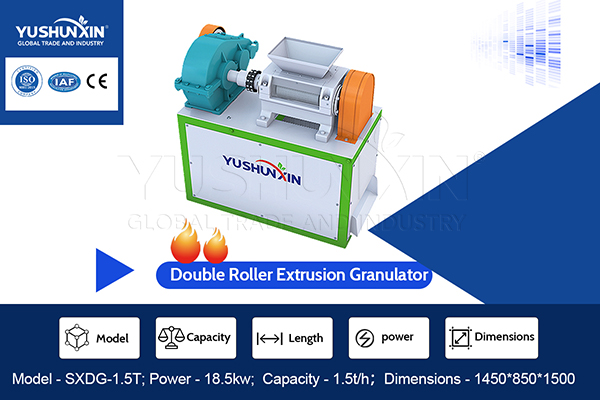

Roller press extrusion method for dried compost pelleting

If your compost material moisture is lower than 30%, the most economical granulation plan of compost is roller extrusion. Only dry compost to 10%-20% water content by sun, you can feeding it to double roller pelletizer. Then the machine can press compost powder into organic granule automatically, without water assist. In addition, there is no drying and cooling in substance processes.

As a reliable granulated compost fertilizer equipment manufacturer, YUSHUNXIN will offer you best solutions to compost granule fertilizer production. Besides, plan to make compost pellets from fresh manure, we also design different solutions with various capacity, materials, budget, etc. Welcome to contact us for your own compost pellets production line.

recently granulated compost solutions