What pretreatment we can do for produce uniform sized fertilizer granules with compost?

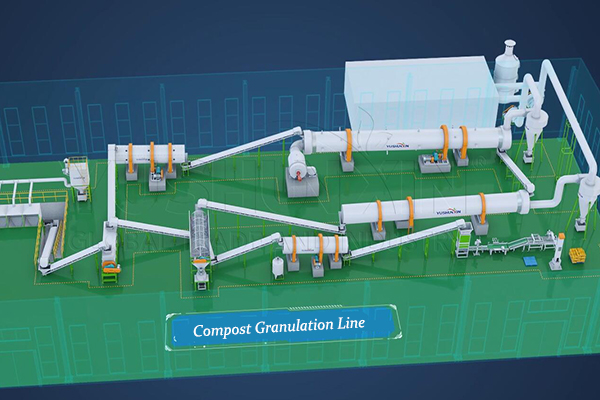

Before feeding material into compost pellet making machine, there are two processes you can do for improving uniform size.

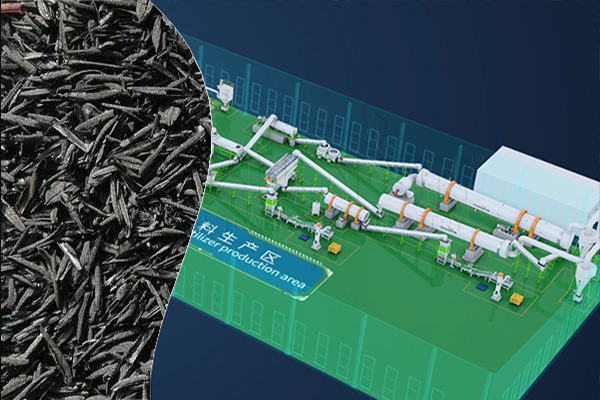

Crushing organic compost into fine powder

After aerobic fermentation, because of 30% moisture, there is usually some agglomerates in decomposed manure. Their large size will hamper the granulation of compost fertilizer. Therefore, it is advisable to break down organic compost into fine powder first. Here, we can offer you various compost grinders for your choice.

Mixing compost with other materials evenly

Then, when you plan to add auxiliary material for making better compost pellet, we recommend you also use a compost mixer before pelleting. Because, mixing the compost powder with additives thoroughly is key to ensuring the consistency of the ingredients.

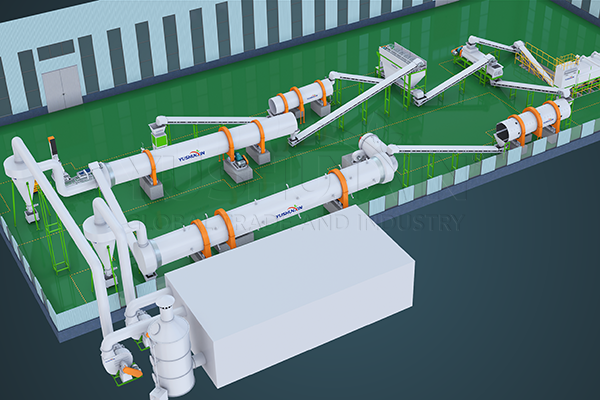

3 Factors affects the uniform size of your compost pellets fertilizer during granulation process

During the granulation process, there are 3 main factors influence to produce uniform sized fertilizer granules. The choice of compost pellet machine, binder addition, and moisture control.

93%-95%

How to make the granulated compost more uniform after the compost pelleting?

If you need to make granulated compost more uniform, YUSHUNXIN can provide you with 2 tips.

You can choose the above method to produce uniform sized fertilizer granules from composting according to your needs. If you have any requirements for compost granule making, welcome to contact us immediately, we will offer you customized granulated compost solutions.