Is there a suitable solution for 30000 T/Y biogas digestate fertilizer granulation plant setup?

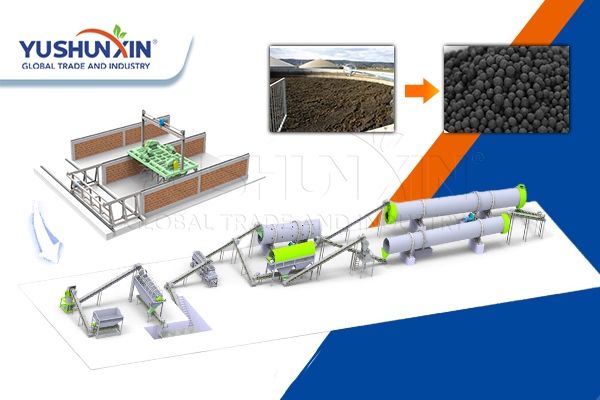

The German customer required a fertilizer business plant for 30,000 T/Y biogas digestate plant. Then, because 20 hour working per day, the best solution is a 5 t/h fertilizer pellet making line, especially with rotary drum granulator.

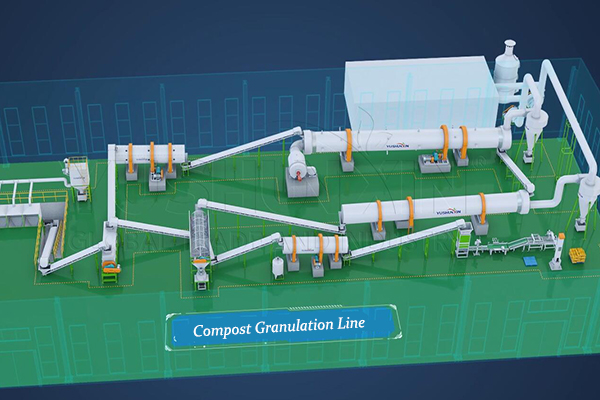

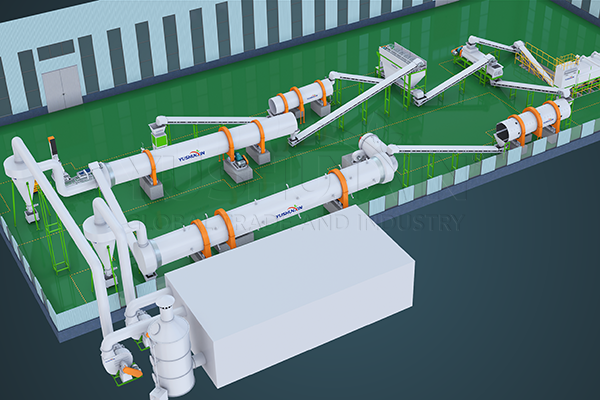

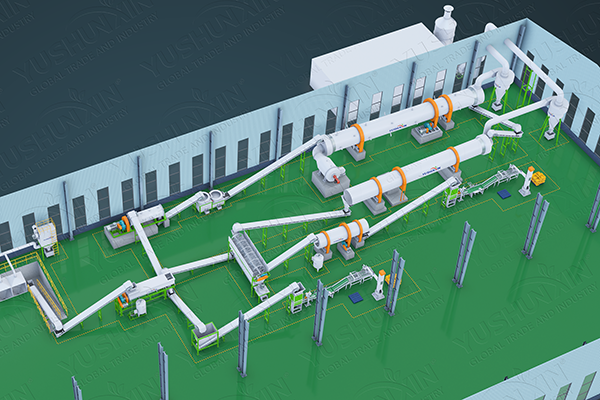

What is the design of a complete rotary drum granulation line for biogas residue compost pellets manufacturing?

Loader type feeder → SXFLF-600 vertical crusher → SXGS-1240 rotary screener → Double shaft mixer → SXZGZ-1560 drum granulation machine → SXGS-1240 granule sieving machine → SXHG-1616 rotary dryer → SXLQ-1616 rotary cooler → semi-automatic fertilizer granule packing scale.

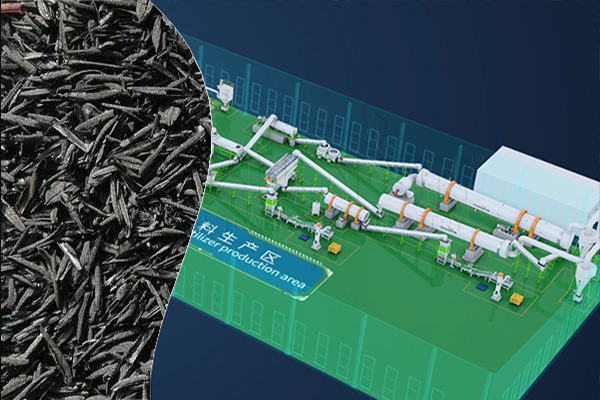

Can the system make compost pellets from biogas residue in 70% moisture?

Of course. But, because the German customer use fresh biogas waste to make granular organic fertilizer, there are two steps he need to do first.

Reducing biogas waste material moisture to lower than 60%

For biogas digestate fertilizer granulation, it requires water content of feeding material is 20%-45%. And, even only compost biogas waste, you also need to reduce the raw material moisture to 40%-60%. To removing excessive water from wet biogas residue, there is screw type dehydrator for you. The machine can reduce the moisture in organic waste to 30%-40% fast.

Turning dewatered organic wasted into compost

In addition, we recommend the client from Germany to compost dewatered biogas digestate waste before drum organic fertilizer granulation. In composting process, pathogens, pest eggs other bad bacteria will be killed thoroughly. The, for 30000 T/Y biogas digestate fertilizer granulation plant setup, SXCF-5000 groove type compost turner is an ideal choice. 5 m turning span and 0.8 m turning depth for composting biogas waste in fermentation trenches. However, compared other industrial composting machines, it has an economical price, only $14,668.

Can offer techno and price parameters for the biogas waste fertilizer machines?

How much does the above 30000 T/Y biogas digestate fertilizer production line cost? Its EXW price is 153,347 USD. Some of the main parameters are as follows:

| Equipment | Model | Capacity (T/H) | Power (kw) | Cost |

|---|---|---|---|---|

| Screw Type Dehydrator | SXTS-180 | 3-5 | 4 | $3,645 |

| Groove Type Compost Turner | SXCF-5000 | 2400 m³ | 40 | $14,668 |

| Loader Type Feeder | SXCWL-2030 | 3-5 | 11 | $5,394 |

| Vertical Crusher | SXFLF-600 | 3-5 | 22 | $3,656 |

| Double Shaft Mixer | SXSJ-8030 | 2-5 | $4,954 | |

| Rotary Drum Granulator | SXZGZ-1560 | 3-5 | 75 | $17,503 |

| Rotary Screener | SXGS-1240 | 3-5 | 4 | $2,548 |

| Rotary Dryer | SXHG-1616 | 6-8 | 15 | $29,815 |

| Rotary Cooler | SXLQ-1616 | 6-8 | 15 | $22302 |

| Fertilizer Packing Scale | 4-10 bag/min | 1.29 | $6,182 |

In addition, it also needs gas burner, air fan, some belt conveyors and other auxiliary machines for biogas residue fertilizer pellet manufacturing.

How long it will take biogas digestate fertilizer equipment shipment to Germany?

YUSHUNXIN fertilizer equipment factory is located in Xingyang City, Zhengzhou City, Henan Province, China. So, after about 30 days, you can receive the biogas digestate fertilizer granulation plant equipment. The freight for biogas digestate fertilizer equipment typically takes about 30-40 days. Once the boat sets sail, I will provide you with the tracking number. This tracking number will allow you to monitor the location of your biogas digestate fertilizer equipment in real-time. You can check the progress of the shipment and get updates on estimated arrival times.

The above are details about our communication with the customer about 30000 T/Y biogas digestate fertilizer granulation plant setup in Germany. In addition, we also can offer you customized compost granule making plans with other materials and capacity. Such as chicken poop compost granulating line, 20 T/H organic compost pellet making system, etc. Welcome to contact us for your own granulated compost production solutions and machinery.

Content

- Is there a suitable solution for 30000 T/Y biogas digestate fertilizer granulation plant setup?

- Can the system make compost pellets from biogas residue in 70% moisture?

- Can offer techno and price parameters for the biogas waste fertilizer machines?

- How long it will take biogas digestate fertilizer equipment shipment to Germany?

More Cases