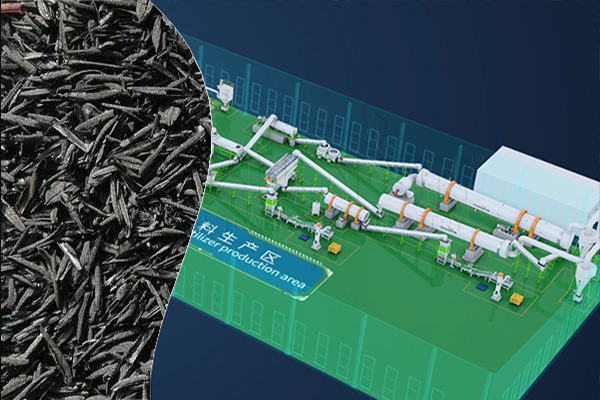

How to design double roller granulator?

In order to manufacture quality double roller granulator, we strictly control from the design. So, we will do processes as follows:

Material Selection to manufacture double roller granulator

The material of the compost granulation equipment depends the final quality and service life. Therefore, we use high quality steel as material.

What is the process of double roller press machine manufacturing?

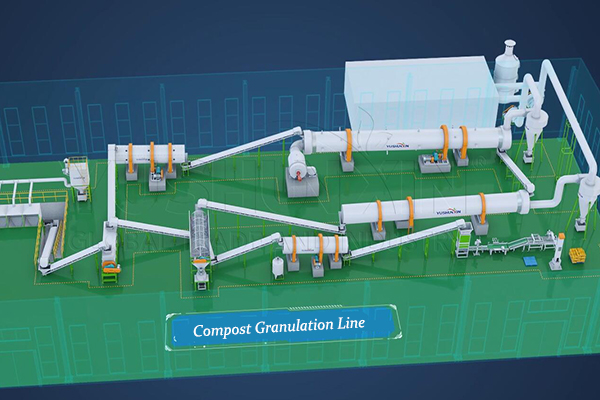

As professional granulated compost equipment manufacturer, YUSHUNXIN has years experience of roller extrusion granulator. The whole process mainly contains 3 parts:

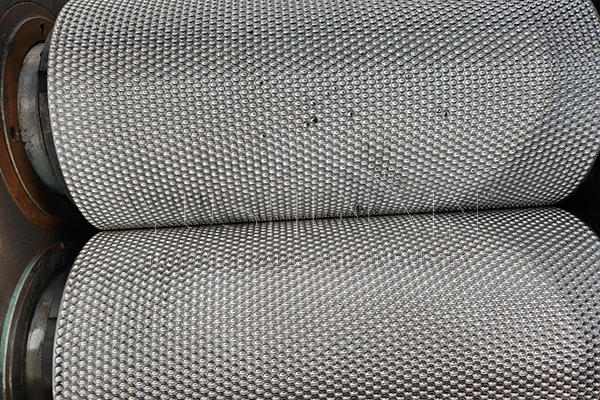

Roller sheet manufacturing

As mentioned above, the roller sheet plays an important role in double roller granulation machine manucturing. A quality roller sheet manufacturing usually needs 4 steps. Including cutting raw material, hollow out, quenching and sculpture.

Body production of roller press granulator

Besides the roller sheets, the body is also an important part of compost fertilizer roller granulator. For this, it usually needs 3 steps.

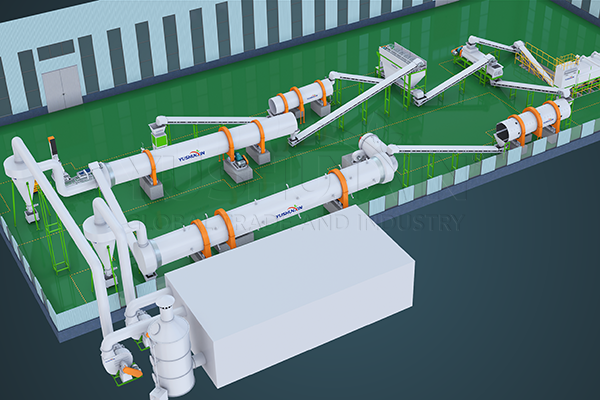

Surface treatment of the dry extrusion machine

Then, we will testing the quality and operation of the finished double roller granulator for compost pelleting. This ensure that the machine you receive can help you make compost pellet smoothly.