Top 3 wet granulation equipment for granulated compost fertilizer production

The wet granulation method is a popular choice for producing granulated compost fertilizer due to its efficiency and effectiveness. Here are the top 3 wet granulation machine options, designed according to your needs.

Most economical wet granulator for compost – pan pelletizer

The pan pelletizer, also known as a disc granulator, is the most economical option for compost granulation. It features over 93% granulation rate, easy operation, and small area occupation, making it ideal for small to medium-sized operations. Especially, 1-6 t/h compost fertilizer granulation plant. The pan pelletizer works by rotating a flat disc, where the compost material is sprayed with a liquid binder and gradually forms into granules. So, it also can meet your requirements of round ball compost granule making.

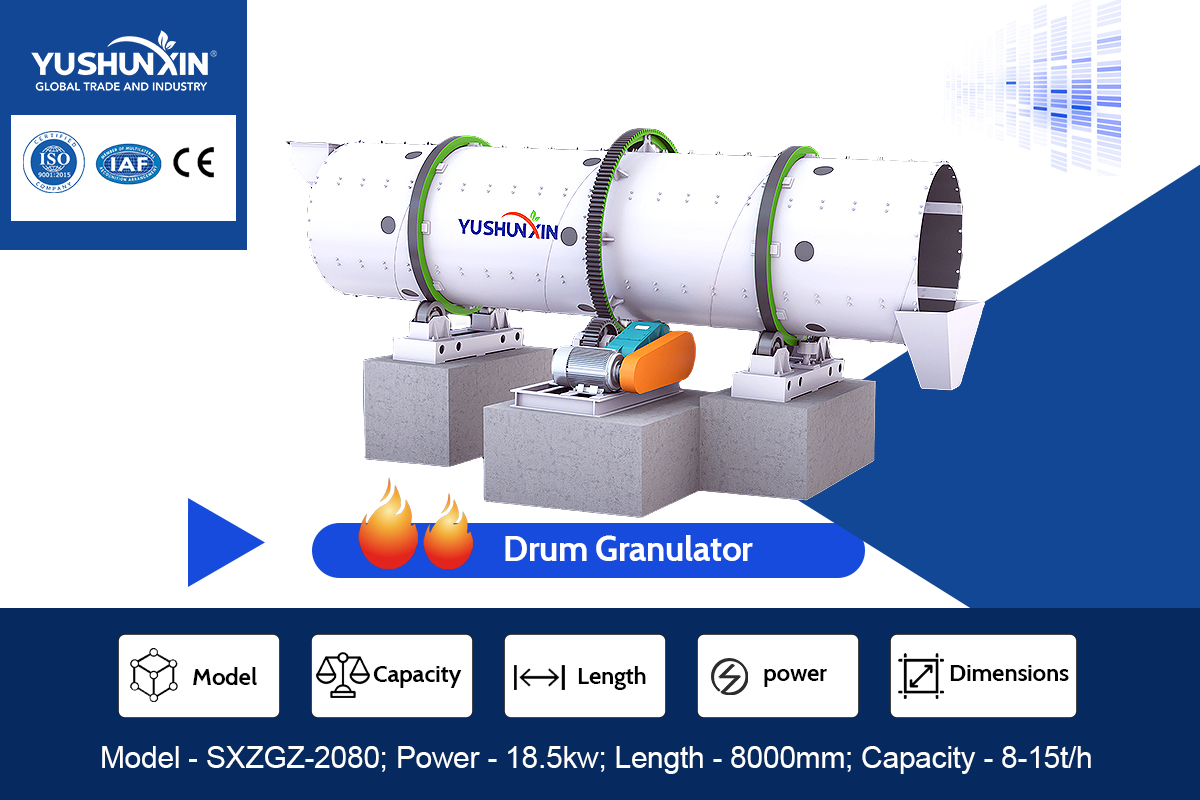

Best wet granulation machine for large scale composting – rotary drum granulator

For large-scale composting operations, over 10 t/h, the rotary drum granulator is the best choice. This wet granulation equipment is designed with rotary drum body to handle substantial volumes of compost material efficiently. With the cylindrical drum rotation, compost and liquid binder will mix. While the continuous tumbling action also ensures uniform granule formation from wet compost quickly. Moreover, it can withstand the equipment erosion from large scale wet compost granulation because of designs of rubber lining and sticking prevention holes. So, the drum granulation machine usually is the go-to option for industrial organic fertilizer manufacturers.

Improve the quality of granulated compost – new type organic fertilizer granulator

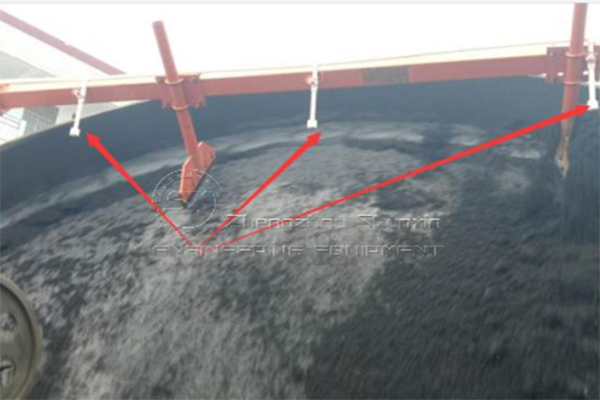

Finally, if you want to enhance the quality of granulated compost. We recommend you buy a new type organic fertilizer granulator. Because, besides wet granulation method, the machine also adopts more powerful mechanical force assistance. It is the friction between stirring teeth and equipment wall. In this way, it brings your compost granule production a 97% granulating rate and harder fertilizer pellet products. In addition, the stirring teeth mixing is also beneficial for prevent material sticking in the wet compost to fertilizer pellet process.

| Equipment | Capacity (t/h) | Granule Size (mm) | Granulation Rate | Feeding Moisture |

|---|---|---|---|---|

|

Rotary Drum Granulator |

1-30 | 3-6 | 90% | 20%-40% |

|

Disc Granulator |

1-6 |

1-8 | 93% | 20%-40% |

|

New Type Organic Fertilizer Granulator |

1-8 |

2-5 |

97% |

20%-40% |

What is the price of wet granulation machine of compost?

Generally, the price of wet compost granulation equipment is related to various aspects. Including type, output, material, design, etc. There is the YUSHUNXIN’s organic fertilizer granulator of wet compost cost for your reference.

If you want to get more precise quote for compost fertilizer pelletizer, welcome to contact us immediately.

How to control the moisture for wet granulation machine of compost?

In the process of wet granulation of compost fertilizer, it is advisable to keep the moisture to 30%-45%. but, how to control the moisture for smoothly compost pelleting with wet granulation method?

Before the compost wet granulation equipment

As mentioned above, before starting the wet granulation of compost fertilizer, you need to ensure the compost material moisture is lower than 45%. If it is higher than 45%, fertilizer dehydrator is an ideal choice. It can dry the wet organic material (50%-90%) to 30%-40% quickly. In addition, if your material is wet manure without composting, we also can offer you suitable composting machine. It not only can make organic manure into compost and also reduce the moisture into 30%.

During the wet granulation process of compost

With the granulation of compost, the moisture in composted organic material will decrease. Sometimes, you need to add the liquid to ensure the water content is higher than 30%. Which is key to making compost pellet fast. Here, we can offer you disc or drum granulator with spray device. Which help you control the liquid adding volume precisely.

How many steps of wet granulation process for compost pellet making?

For making wet compost into quality organic fertilizer pellets, you may also needs some other organic fertilizer machines.

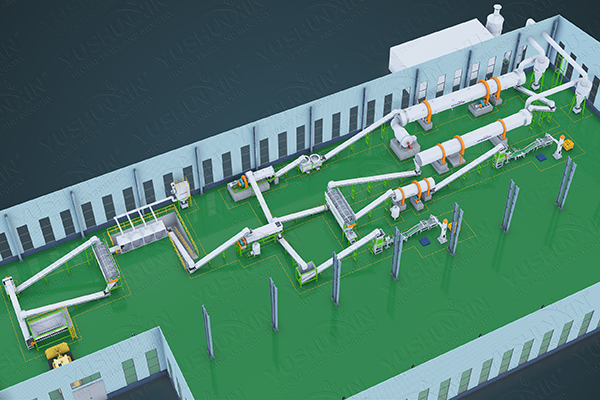

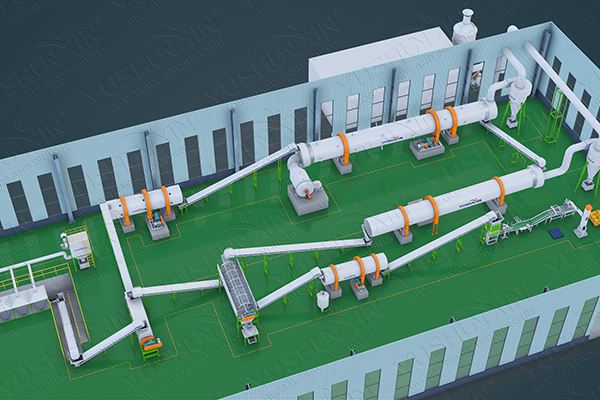

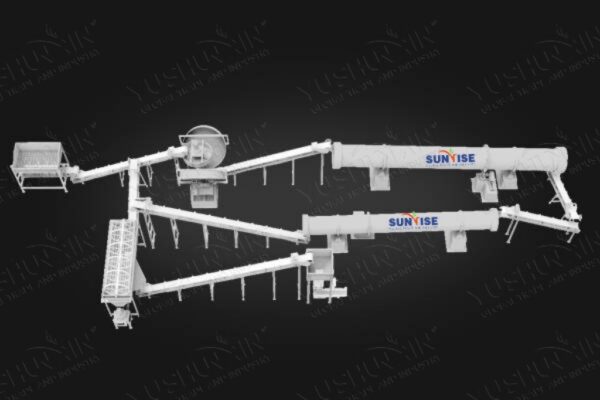

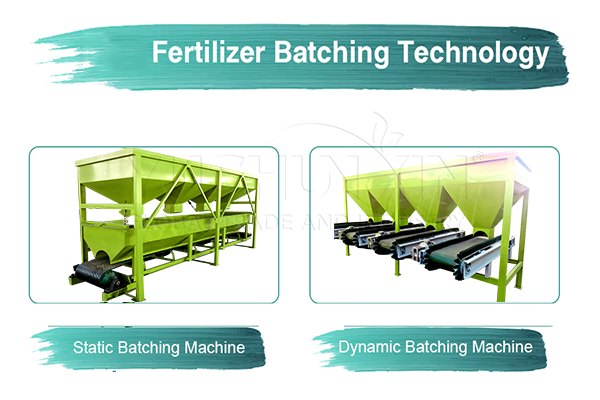

Therefore, a complete wet granulation process of compost consists of batching equipment, crusher, mixer, wet granulation machine, screener, dryer, cooler, coating machine and packing scale.

Besides wet fertilizer granulation method, there also dry granulation system for dried compost to organic fertilizer granules. If you want to start a compost fertilizer granulation plant, welcome to contact us immediately. We will provide you with the best granulated compost solutions according to your requirements.

recently granulated compost solutions