Compost Granulating Machine

Application

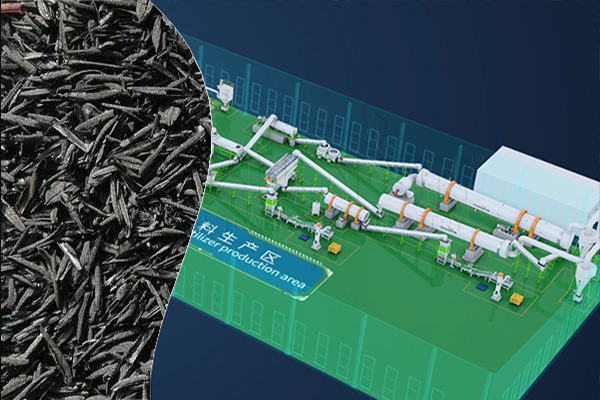

Animal manure, biogas waste, industrial organic waste compost, humus, biochar compost, etc

Capacity: 1-30 t/h

Granule Size: 1-10 mm

Granulation Rate: 90%-97%

A compost granulating machine is a vital piece of equipment in an organic compost pelleting line. The machine is designed to transform composted organic waste into granules quickly and easily. In order to meet your requirements for 1-30 t/h granulated compost fertilizer making, we especially design disc granulator, new type organic fertilizer granulator, rotary drum pelletizer and roller press granulation machines for your choice. With quality equipment material, high granulation rate, economical price, these machines will help you start the production of granular compost fertilizer smoothly and successfully.

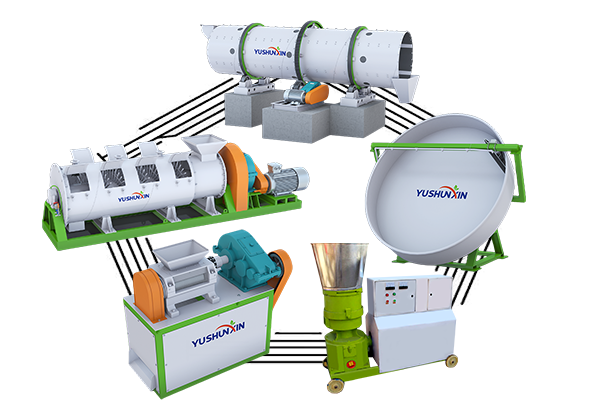

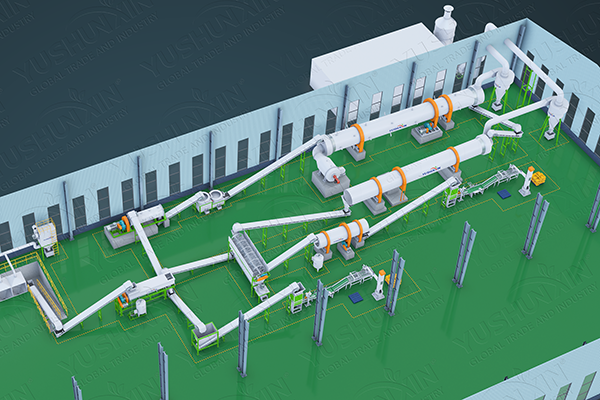

1-30 t/h compost granulating machines for sale in YUSHUNXIN

In order to meet your requirements of turning compost into organic pellet in both small scale and large scale, YUSHUNXIN offers a comprehensive selection of compost granulating machine. They can cater to various scales of compost fertilizer manufacturing, from 1 t/h to 30 t/h.

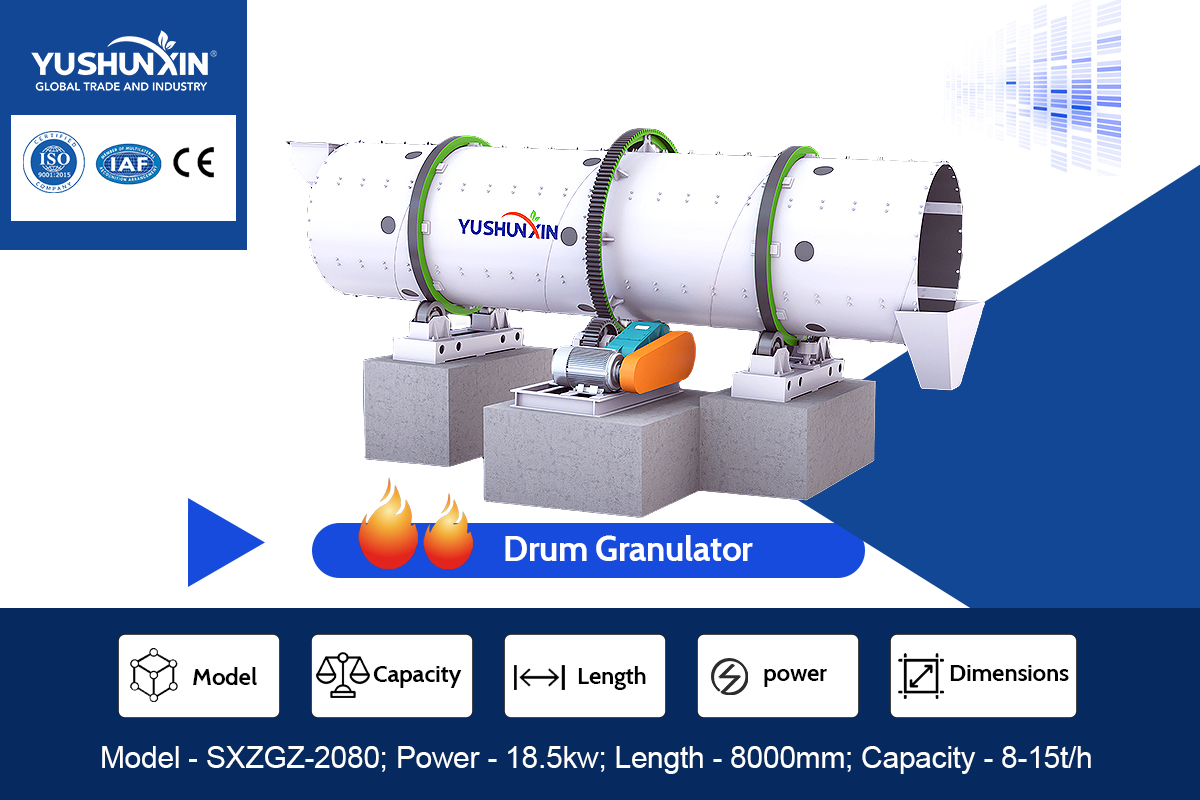

1-30 t/h drum pelletizer for industrial fertilizer granule making from compost

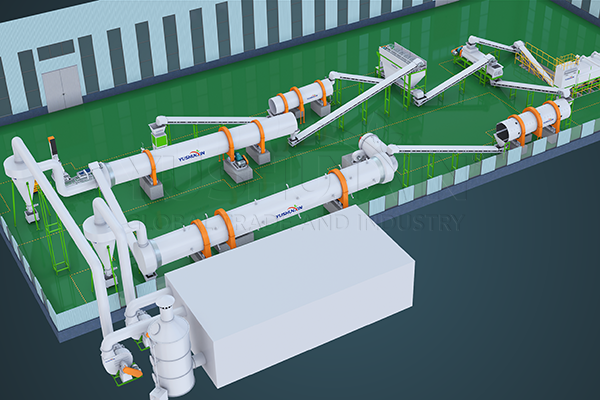

For large-scale industrial compost pellet making plant setup, we recommend you the rotary drum pelletizer. Because, it can transforming large quantities of compost into uniform organic fertilizer granules in a short time. The machine is capable of produce 1 to 30 tons of granuled compost fertilizer per hour. In addition, it has unique designs of rubber lining and sticking prevention holes. Therefore, the drum granulator can withstand the long time processing of compost pellets and prevent material sticking and waste.

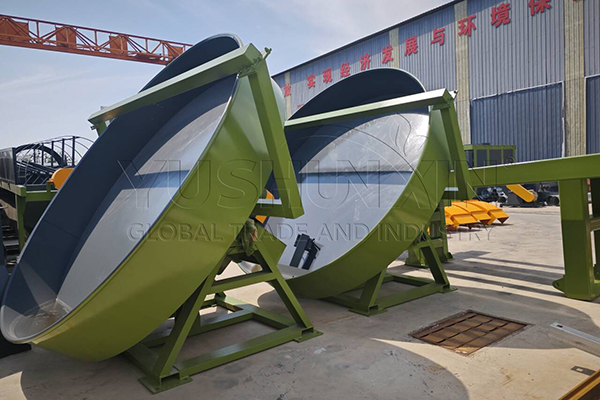

1-6 t/h disc pellet machine for small scale compost fertilizer granulation

However, for these who want to start a small scale compost fertilizer granule production business, there is a more economical compost granulating machine. Especially, for 1-10 t/h capacity. It is disc granulator. For one thing, the price of disc granulator is more favourable than other compost pellet making machines costs. For another, its compact size fits well into small compost fertilizer granulation plant establishing. Generally, the output of pan pelletizer is 1-6 t/h But, when use 2 sets of pan granulation machines, you can finish the production of 10 t/h pelletized compost easily. So, disc pellet machine purchasing is a smart investment for small-scale organic compost granulation operations.

1-8 t/h new type organic fertilizer granulator used after composting

In addition, if you purse a high granulation rate and hard compost granules making, there is also new type organic compost granulator for you. The machine makes use of friction between stirring teeth and equipment wall to enforce compost powder convert into organic fertilizer granules. In this way, the granulation rate of compost pellet making can reach 97% and the granulated compost hardness is about 15-20 N. How about the capacity of the organic fertilizer granulator of compost? 1-8 t/h, which can fully meet your needs to small-medium compost organic fertilizer granules manufacturing.

How to make organic fertilizer pellets from dried compost quickly?

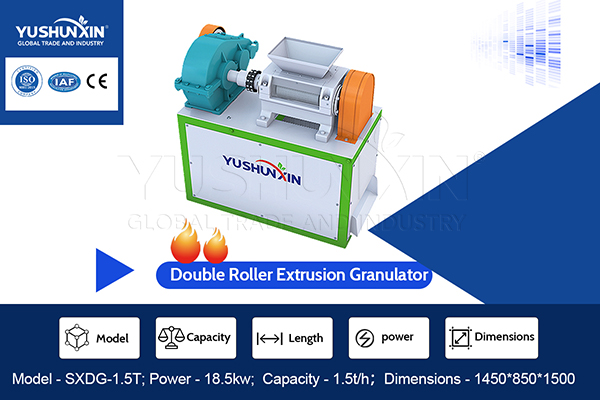

The above 3 types of compost pellet machines all granulate organic compost in wet conditions, can we make dried manure into compost pellets directly? Of course. You can choose to buy our dry granulation machine for compost pelleting. It mainly makes use of roller extrusion to press compost powder into fertilizer granules. So, there is nearly no water involved. What’s more, only needs one squeezing, it can complete the granulation of organic composting. Therefore, you can produce granulated compost fertilizer quickly. For this, we design 2 types dry compost granulation machines for your choice. Double roller granulator and flat die mill. The former has a capacity of 1-3 t/h and prepare flat ball compost pellets for you; while the latter only make 1-1.5 tons of compost pellets per hour, with column shape.

Can we make round ball compost pellets with dry granulation equipment?

It is dispensable. On the one hand, the compost pellet produced from disc and drum granulator will pulverize under the action of high speed rotating. On the other hand, the granulated compost from the above the round ball compost pellet machines can fully meet your requirements.

Top 3 FAQ about compost pellet making machine from granular fertilizer manufacturers

Besides the types, there are many other aspects you need to pay attention to when buy compost granulating equipment. For example,

| Equipment | Capacity (t/h) | Granule Size (mm) | Granulation Rate | Feeding Moisture | Equipment Material |

|---|---|---|---|---|---|

|

Rotary Drum Granulator |

1-30 | 3-6 | 90% | 20%-40% |

Carbon steel Q235 + rubber lining |

|

Disc Granulator |

1-6 |

1-8 | 93% | 20%-40% |

Carbon steel Q235 |

|

New Type Organic Fertilizer Granulator |

1-8 |

2-5 |

97% |

20%-40% |

Carbon steel Q235 + Manganese steel |

| Double roller granulator | 1-3 | 3-10 | 95% | 5%-15% |

Carbon steel Q235 + 20GrMoTi |

How much is the compost granulating machine price?

The cost of a compost granulating machine can vary widely depending on several factors. Such as its capacity, types, construction materials, manufacturer, and additional features. Typically, the compost granulating equipment prices range from a few thousand dollars to over $70,000 USD. As a reliable fertilizer equipment manufacturer of compost organic fertilizer granulation, YUSHUNXIN can offer you an economical factory price.

For the most precise pricing of compost pellet machine you need, Welcome to contact us directly.

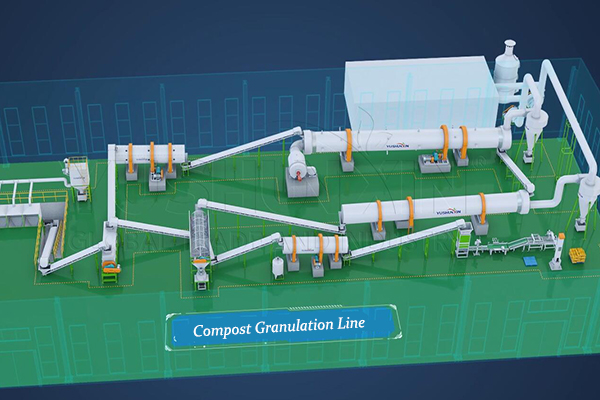

What other machines we need for commercial organic fertilizer granules making from compost?

For commercial fertilizer granules production with compost, there are many other machines plays critical roles:

Together, these machines establish a robust production line for creating high-quality organic fertilizer granules from compost on a commercial scale.

Contact Us

recently granulated compost solutions

Granular Compost Fertilizer Drum Coating Machine

Auxiliary Equipment• 1-30 T/H

How To Produce Granular Biofertilizer From Compost

Project • 1-20 T/H • 1-10 mm Granules

Groove compost fertilizer machine for economical compost granulation

Compost Machine • 2-5m turn width • 15-20 days