When buy a drum granulator for making fertilizer pellets from compost?

When producing organic fertilizer pellets from compost on a industrial scale, many organic fertilizer manufactures employ a drum granulator. Especially, when under you are in the following conditions:

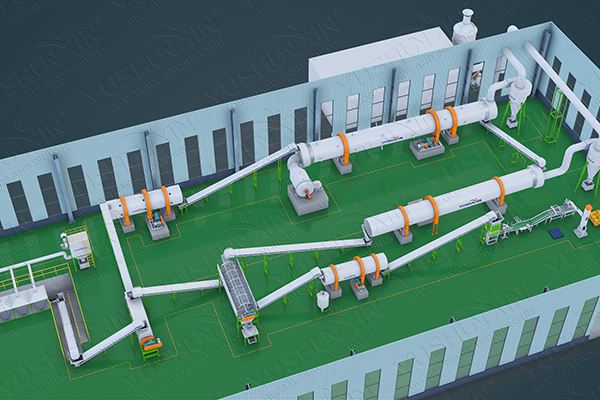

Large scale industrial organic fertilizer granulation plant setup

For operations producing significant volumes of compost pellets, the continuous and efficient nature of drum granulator is indispensable. In addition, besides model for small scale organic compost fertilizer granulation, it also contains rotary drum pelletizer with large output. Its maximum capacity of compost pellet production can reach 30 t/h.

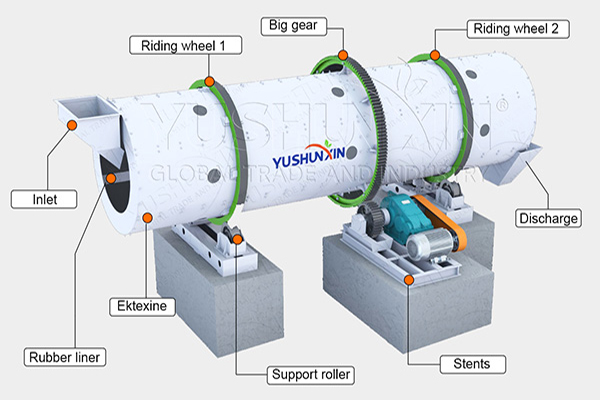

Buy a erosion-resistant compost pellet machine

In general, when you focus on the erosion-resistance of compost fertilizer granulator, we recommend you buy a rotary drum granulator. For one thing, it adds a rubber lining inside the drum. In this way, it can withstand the large scale compost granule making for a long time. For another, we design hitting holes for the drum granulator of composting. Only need to hit the holes with a hammer, the compost material sticking to the wall will fall and form into new compost pellets.

Using wet compost to make organic fertilizer granules

In addition, rotary drum granulation machine also has excellent performance in granulate wet compost, which has a certain level of moisture. It can process 20%-40% water content composted organic material into fertilizer pellet quickly. Because, the machine makes use of liquid as binder to encourages the compost powder to clump together and form granules. This process is not just beneficial for decomposed organic fertilizer pellet making but also help you start the granulation after composting immediately.

Round ball granulated compost production

This machine is also suitable for organic fertilizer granulation plants that want to produce round ball granule with compost. Drum granulators are particularly adept at producing these round pellets, which are easier to spread, less likely to break down during transport, and have an appealing aesthetic. The tumbling action within the drum compost pellet machine naturally rounds off the edges of the forming fertilizer pellets.

| Model | Power (kw) | Diameter (mm) | Length (mm) | Installation Angle | Rotary Speed (r/min) |

Capacity (t/h) |

|---|---|---|---|---|---|---|

|

SXZGZ-1240 |

5.5 | 1200 | 4000 | 2-5° | 17 |

1-3 |

| SXZGZ-1560 | 11 | 1500 | 6000 | 2-5° | 17.5 |

3-5 |

|

SXZGZ-1870 |

15 | 1800 | 7000 | 2-5° | 11.5 | 5-8 |

| SXZGZ-2080 | 18.5 | 2000 | 8000 | 2-5° | 11 |

8-15 |

|

SXZGZ-3210 |

37 | 3200 | 10000 | 2-5° | 9.5 |

15-30 |

How does a rotary drum granulator work to turn compost powder into organic fertilizer granules?

As mentioned above, the drum granulator of composting makes use of liquid as binder. This is called wet granulation method in granulated compost making. The details of the drum granulation process of compost contains 4 steps.

Other Commonly FAQ about drum granulator of composting?

Then, the best way to buy a suitable granulation machine of compost is looking the final granulated compost fertilizer. Such as granule size, moisture, granulation rate, etc. How about these of compost pellets from disc pelletizer?

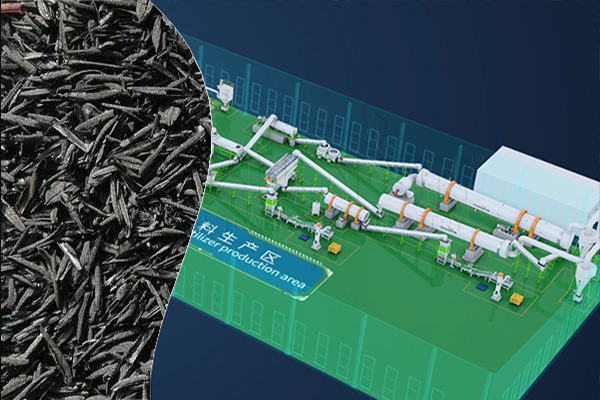

What types of organic materials can be processed with a drum granulator?

Generally, most types of compost material can be made into fertilizer pellet by the rotary drum pellet machine. Such as cow dung manure compost, chicken poop compost, biochar compost and even the mixture of compost with NPK, etc.

How can we control the size the compost granules produced by the drum granulator?

For compost fertilizer granule size control, there are two ways you can use. On the one hand, adjust the moisture. The less the water, the smaller the size; the much the water, the larger the size. On the other hand, control the speed of drum rotating. The higher the speed, the smaller the size; the lower the speed, the larger the size.

What type of binder can be used in the drum granulation process of compost

Commonly, you can choose to use water, humus, bentonite, etc freely.

In addition, if you only has fresh organic waste as material for organic fertilizer granule making, YUSHUNXIN also can offer you dewatering machine and industrial compost machines for your choice.

recently granulated compost solutions