Search Granulated compost solutions you need!

5-10% Off Now!

-YUSHUXNIN FERTILIZER EQUIPMENT MANUFACTURER

We provide best granulated solutions and machines for you

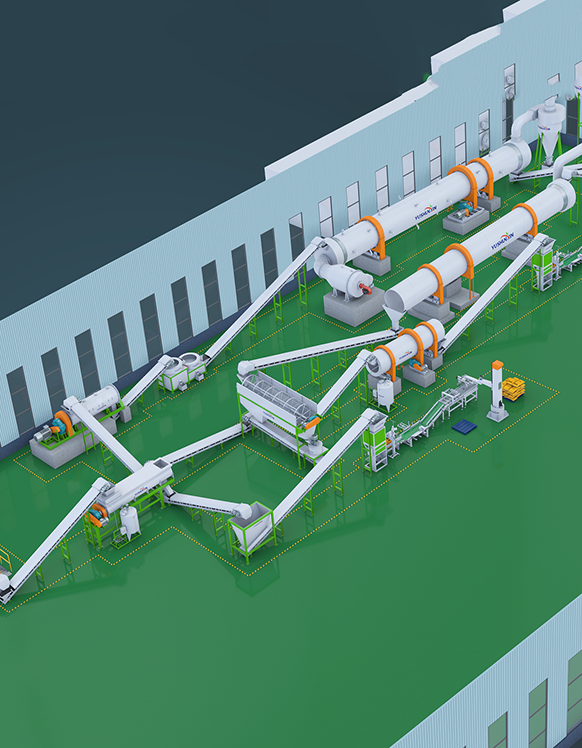

With more than 20 years of experiences on advanced compost granulating machines manufacturing. YUSHUNXIN fertilizer equipment earn the trust and praise of customers at home and abroad.

Latest Granulated compost solutions

Discover the latest granulated compost solutions design in YUSHUNXIN fertilizer equipment company. Get the best granular compost pellet plan and machinery for you.

why choose us

If you want to buy equipment for your compost to organic fertilizer pellets project, YUSHUNXIN Engineering Equipment

Granular compost fertilizer Production Cases

There are some cases of our past customers for granulated compost fertilizer production plants setup for your reference.

Contact Us

News & FAQ

Both industrial and company news are here. And all you want to know about compost pelleting equipment and technoloies.

Can you make round organic fertilizer pellets with double roller granulation?

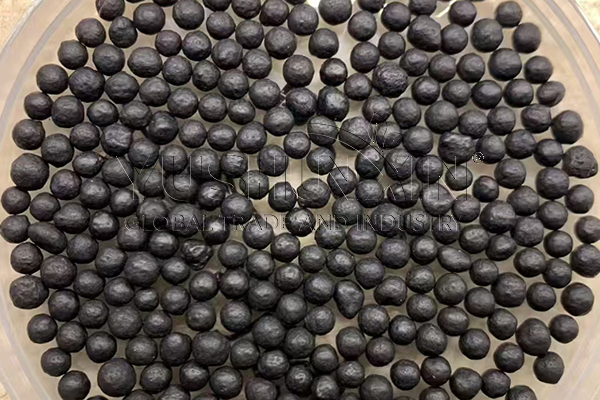

Yes, absolutely. The double roller granulator process forms dense, uniform compost fertilizer granules. Then using the fertilizer polishing machine after granulation improves the roundness of fertilizer granules. With this simple addition, your dry granulation system for composted manure processing can produce premium, spherical organic fertilizer pellets. Which are suitable for packaging and field application.

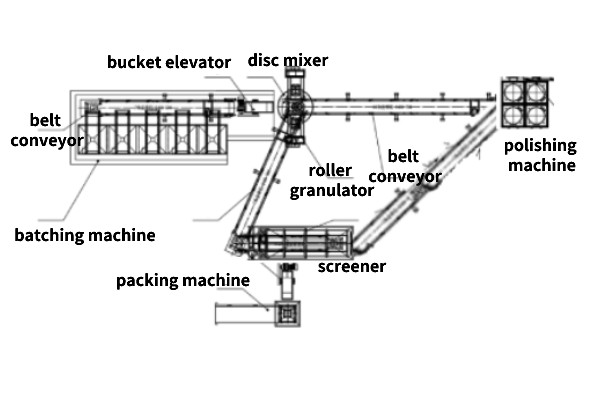

What is the design of a round ball fertilizer production line with dry extrusion granulation?

What is the design of a round ball fertilizer production line with dry extrusion granulation?

Moreover, according to your equipment, we can offer you customized roller granulation solutions for spherical organic fertilizer pellet making. Such as, you can add the drying system to quickly reduce moisture content, the fertilizer pellet coater to process bio fertilizer or slow-release fertilizers, and bucket elevators for better space utilization in smaller plants. Come to get your own compost granules production plan.

How much does the cost of a complete double roller granulation line for round ball organic fertilizer making?

The total round organic fertilizer production line price depends on your required capacity:

Besides, there are also more systems for turning compost into organic fertilizer pellets in round shape in YUSHUNXIN. Such as, economical disc granulation line, industrial rotary drum granulation plan, stirring teeth pelletizing system for hard granule making, etc. Welcome to contact us for them immediately!

What is the process to make slow release fertilizer pellets from compost?

In general, preparing compost fertilizer granules with slow releasec performance contains 5 parts.

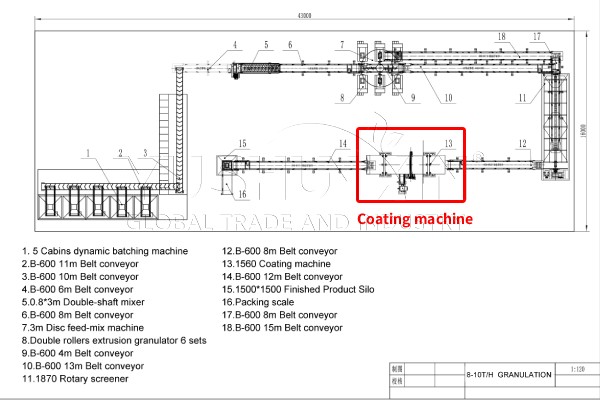

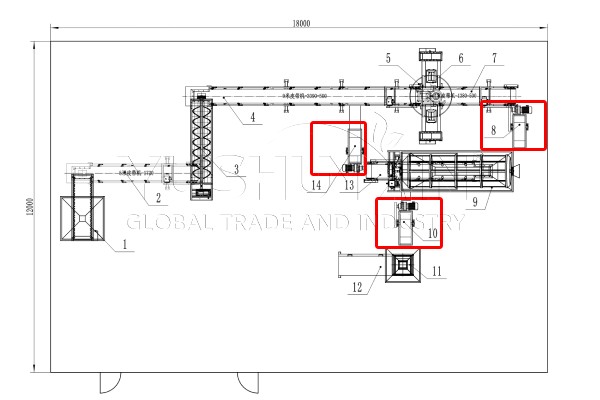

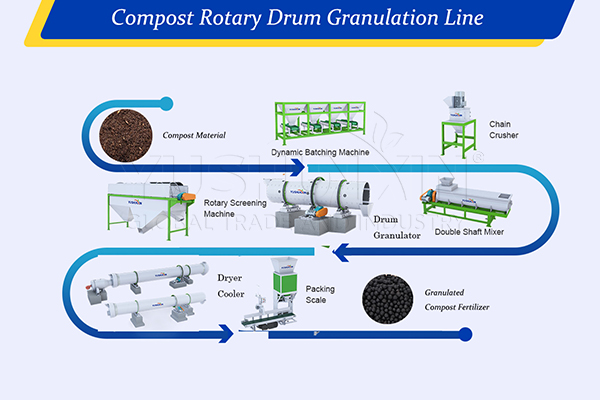

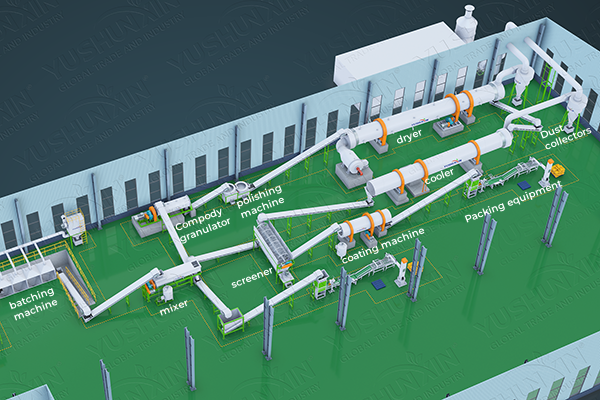

In sum up, the whole system to make slow release fertilizer pellets from compost consists 8 equipment. Batching machine, compost grinder, mixer, pelletizer, dryer, cooler, coating machine and bagging equipment. These pelletized organic compost fertilizer, when applied to soil, gradually release nutrients, supporting plant growth over an extended period.

how to add Slow-Release Agents when make slow release fertilizer pellets from compost?

To incorporate slow-release functionality with your granular compost fertilizer, there are 2 ways for your choice.

Mixing before slow-release fertilizer granulation

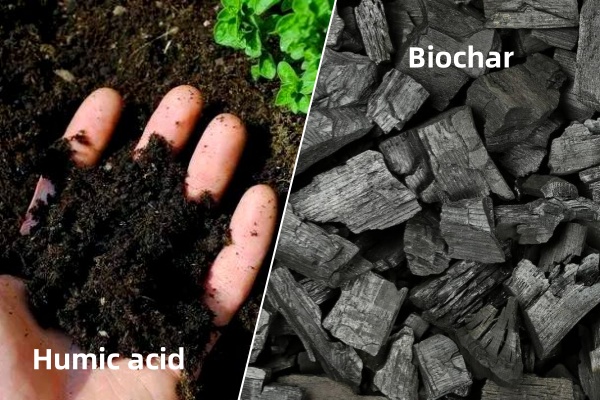

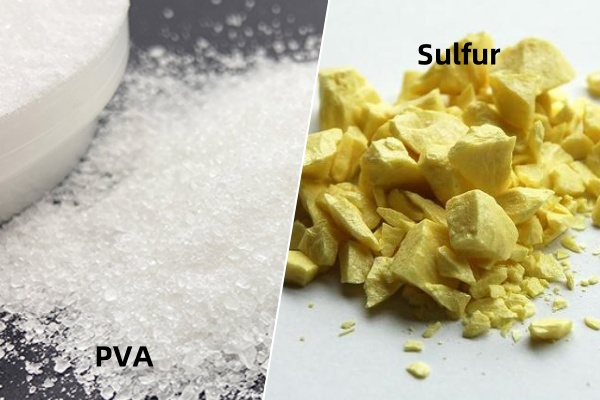

For one thing, you can blend the slow-release additives into the compost material before granulation. After the compost is crushed and screened, the additives (humic acid, biochar, etc.) and binders are mixed uniformly in a horizontal or vertical compost mixer. This ensures even distribution and consistent performance in the final product.

Adding slow release agent during compost pelleting

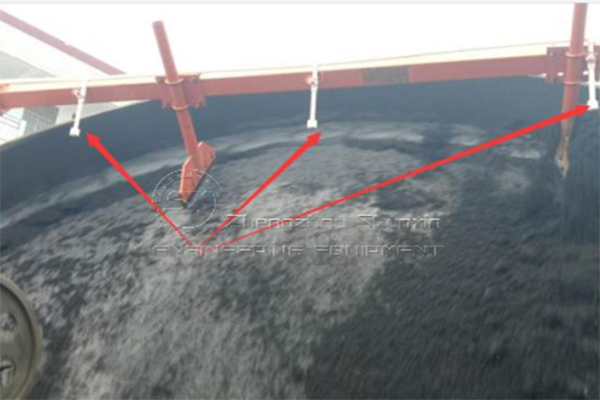

In addition, there are also compost pellet machines with spray device. Including a rotary drum granulator and disc pelletizer. They can add slow-release agent while compost granulation. This is suitable for thoese who only need a slow release fertilizer granulator.

Coating slow release agent film

For another, you also can choose to use a rotary drum coater to apply external layers that slow the nutrient release after pelletizing by a compost granulation equipment. If you plan to process the granulated compost fertilizer into slow-release, this method is recommended.

How long does it take for fertilizer to slow release?

Slow-release fertilizers made from compost typically begin to work within three to ten weeks, as microorganisms break down the nutrients slowly. This gradual process ensures that plants receive a consistent supply of essential nutrients over time. Some slow-release fertilizers can continue to be effective for a few months, and in some cases, up to a year, providing long-term nourishment and reducing the frequency of reapplication. This makes them ideal for maintaining healthy plant growth with minimal effort. So, there are many fertilizer manufacturers investing in project to make slow release fertilizer pellets from compost.

If you want to know more about granulated compost manufacturing solutions and machine, welcome to contact us immediately. There are compost granulation plans range from 1 t/h operation to 20 t/h ouput, from cow dung pelleting to mineral waste compost granulation, etc for your choice.

How to recycle unqualified size particles for reprocess in compost granulation process?

In general, the rate of required size compost pellet making can reach 90%-95% with YUSHUNXIN compost pelleters. It can ensures minimal material loss. Still, to truly granulate compost in no waste, the remaining 5%-10% of granulated compost fertilizer—either too large or too small—must be properly recycled. Commonly, it needs only 2 steps.

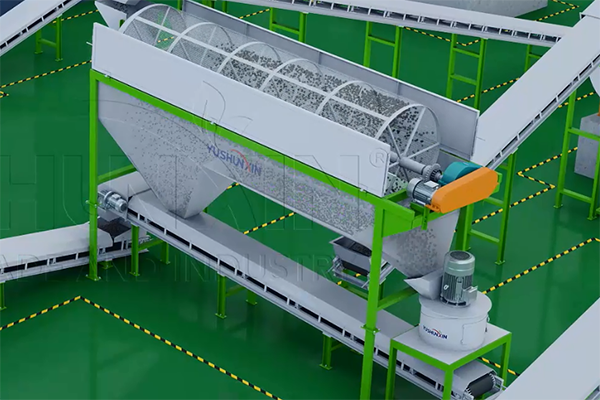

Separate compost granules with required size from the unqualified

First, you need to separate the granulated compost fertilizer pellets from those that do not meet your requirements. For this, rotary drum screener can finish it perfectly. With sieving mesh rotation, it can divide pelletized compost fertilizer into the size of required, too large and too small. There are 1-20 t/h capacity models of compost screeners for you.

Crushing returned fertilizer particles in fine powder

Next, you can grind the unqualified compost granules into fine powder for returning to the compost pellet making machine. For the returned compost pellets crushing the chain crusher is the best choice. Because of small space needed, you can put it closed to rotary screener directly. Namely, it don not need extra belt conveyor.

This system can greatly reduce the material waste in compost granulation plant. If you need the unqualified compost pellet recycling system, welcome to contact us now!

Is there powder dust material recycling system for no waste compost granulation?

Besides granulated compost fertilizer returning, you also can reach zero waste by prevent dust generation. For this, YUHSUNXIN can offer you best solutions, which contains:

Professional dust collectors

First, the most effective solution to recycle the spread powder in compost granulation is use professional dust collectors. Including cyclone dust collectors, water curtain dust collectors, and dust fall rooms. These devices capture airborne particles during compost pellet making, especially in the steps of compost drying and cooling. The compost material in the dust collecting system can be recycled to prepare granular compost fertilizer again.

Fertilizer machine with dust covers

In addition, for further reduce the waste in compost granulation, you can also add dust covers on machine where compost powder is easier to spread. Such as belt convey and screening. Here, YUSHUNXIN can offer you these customized machine to granulate compost in no waste.

In summary, it is entirely feasible to granulate compost in no waste. YUSHUNXIN can offer you the best solutions. Welcome to contact us for your own granulation compost fertilizer manufacturing plan immediately.

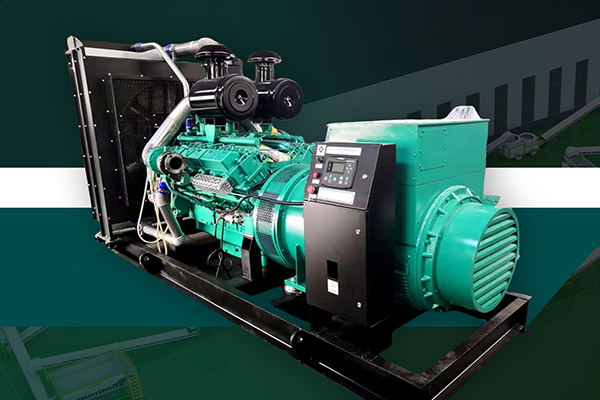

What types of diesel compost pellet mills are available in YUSHUNXIN?

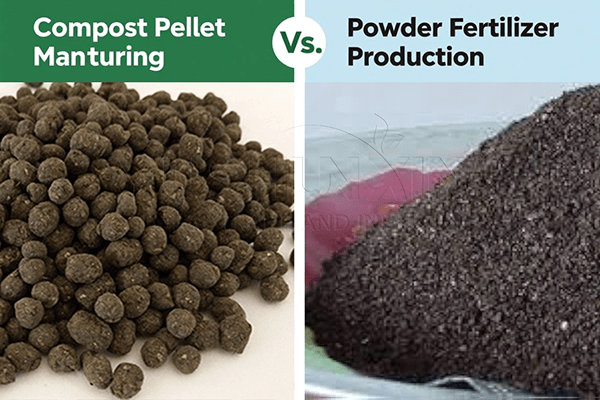

In general, for those who want to produce compost fertilizer pellets with mineral material adding, there are 2 solutions are popular with the manufacturers.

New type organic fertilizer granulator

This new type organic fertilizer granulation machine is designed to efficiently produce compost pellets with high hardness. Its granulation rate of 2-5 mm organic fertilizer pellets making can reach to 95%. At the same time, single set output is 1-8 t/h, which can fully meet your small and large scale organic compost granulation.

Double roller granulation machine

But, the best choice for dry compost pellet production is double roller granulation equipment. This machine uses rollers to compress compost materials into solid organic fertilizer pellets. There is nearly no water involved. It’s especially effective for no drying compost granulation and start the project in water-scarce areas.

Flat die pellet mill

The flat die pellet mill is a more compact option for smaller compost granulation operations. It is user-friendly, easy to maintain, and highly efficient for converting organic compost into uniform fertilizer pellets. So, it is ideal for farms or businesses just starting out.

Is there solution to generate powder for the whole granulated compost making line?

Of course. Besides diesel compost pellet making machines, YUSHUNXIN also prepare large diesel powder generator. This can supply enough electricity for the whole compost granulation line working. Commonly, there are various models of powder generators for your choice.

If you have any other requirements for compost granules making, welcome to contact us now.

How much does a 5 t/h pan compost granules making line cost?

Are you finding equipment for your compost fertilizer granulation plant? Disc pelletizer is an ideal choice when you have requirements as follows:

In general, a complete 5 t/h compost granules making line with pan pelletizer pricing between $120,000-$170,000. Commonly, it contains material feeding machine, compost crusher, fertilizer mixer, pan granulation equipment, dryer, cooler, packing machine, dust collector, etc. The precise quote of the compost pelleting line designs. Like is it need composting or not, dust covers, carbon steel or stainless steel material, etc.

What is the plant operation cost of producing compost granules per day in Russia?

After buying compost granulation line machines, you need to consider the cost for a compost organic fertilizer granulation plant operation. This usually contains workers payment, electricity energy cost, fuel investment, etc.

Here, take the above 5 t/h pan compost granules making line as example. If it cost Rs 500 per man /day , power at Rs 7/ kwHr , Agricultural waste fuel at Rs 10/kg , Furnace oil at Rs 45/kg, etc.

The compost granulating plant approx cost for one day is 38668.8Rs= 500Rs*4 workers+ 154.8 Kw*Rs7/KwHr* 8Hr+350kg*Rs 10*kg *8Hr.

Provided you want to get more precise operational cost of organic compost granulation line you buy, welcome to contact us now. In addition, if you want to know other aspects about compost pellet manufacturing plant setup, YUSHUNXIN also can offer you the best solutions and answers. Including fertilizer equipment powder solution, other granulated compost making line prices and so on.

How large amount of compost to make?

First of all, as the name suggests, you need to ensure the volume of organic waste you need to process. When you want to buy a large composting equipment for over 10 t/h compost granulation plant, wheel type compost turner is the best choice. Because it has a turning span of 8-30 m and turning depth of 1-3 m.

Which fermentation method of large scale composting machine you want to buy?

In the market, there are various machines for large scale compost making. They adopts different composting method and fermentation technologies. Here, you need to buy the best one according to your needs.

how much does the large scale compost machine cost?

Because of large capacity and advanced technology for better composting, the prices of large scale composting machines are between $20,000-$60,000. As mentioned above, wheel type compost turner is the most economical one. Usually, a 10 m compost span one pricing $33,600

what is the material of the large scale composting equipment?

Commonly, in order to reduce the erosion from large compost production to fertilizer fermentation equipment, we will manufacturing large composting machine body with carbon steel, which has a high strength. In addition, for compost turning parts, we will add a film of anti-corrosion paint. Or we can replace it with manganese steel and stainless steel according to your requirements.

What type of organic waste material to decompose?

In general, YUSHUNXIN fertilizer fermentation equipment is suitable for almost all types of organic waste composting. Such as

Therefore, whether you buy the large fertilizer compost turner for organic waste management or commercial compost granules making, our equipment for mass production of compost can fully meet your needs.

How to find the reliable large scale composor manufacturer

After determining type of large fermentation machine you want to buy, it is advisable to find a reliable compost machine manufacturer. It is better to has advantages as follows:

Source factory for fertilizer compost equipment

Therefore, you can get the favourable price to buy the large composting equipment.

Considerate after-sale service

Timely solutions to composting turner installation, operation, compost production, etc.

By following these steps, you can make a well-informed decision when purchasing a large-scale composting machine, ensuring it meets your operational needs of compost fertilizer making and contributes effectively to your compost pellet manufacturing goals.